|

Applicable to TC-1 to TC-1607, TE-1 to TE-942, Except TE-938

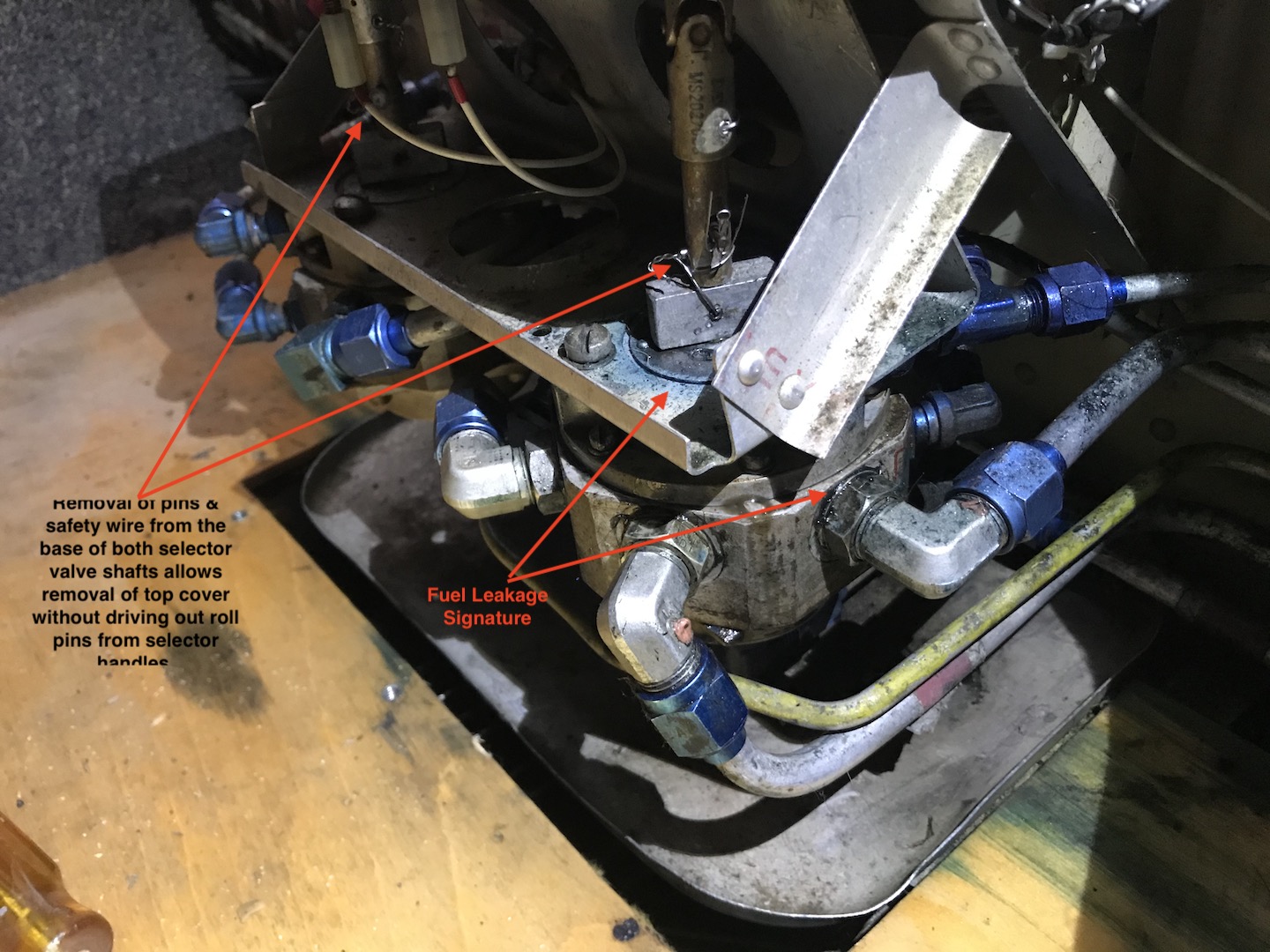

Got blue stains in the tray underneath your

fuel selector? Got blue staining on the body of your fuel selector? See

HERE for examples

of fuel staining of a Bonanza fuel selector body (Click

HERE if you need

Bonanza fuel selector O-Rings).

Did someone quote you an

incredibly high price to OVERHAUL your fuel selectors (I can't understand why,

because there's only o-rings in there that any A&P is authorized to remove and

replace). However, it is a rather tedious and critical process as you will see

in this teardown narrative.

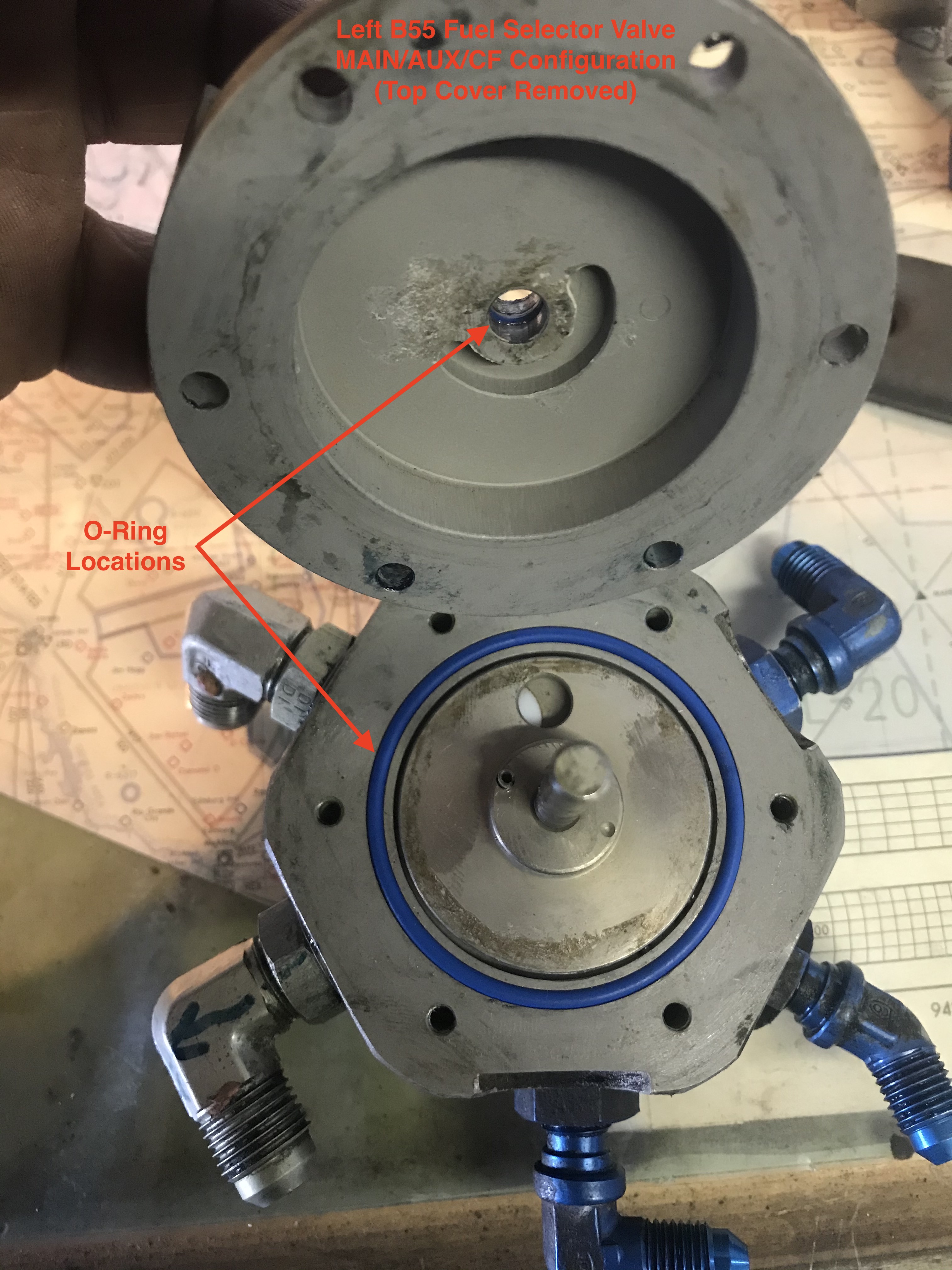

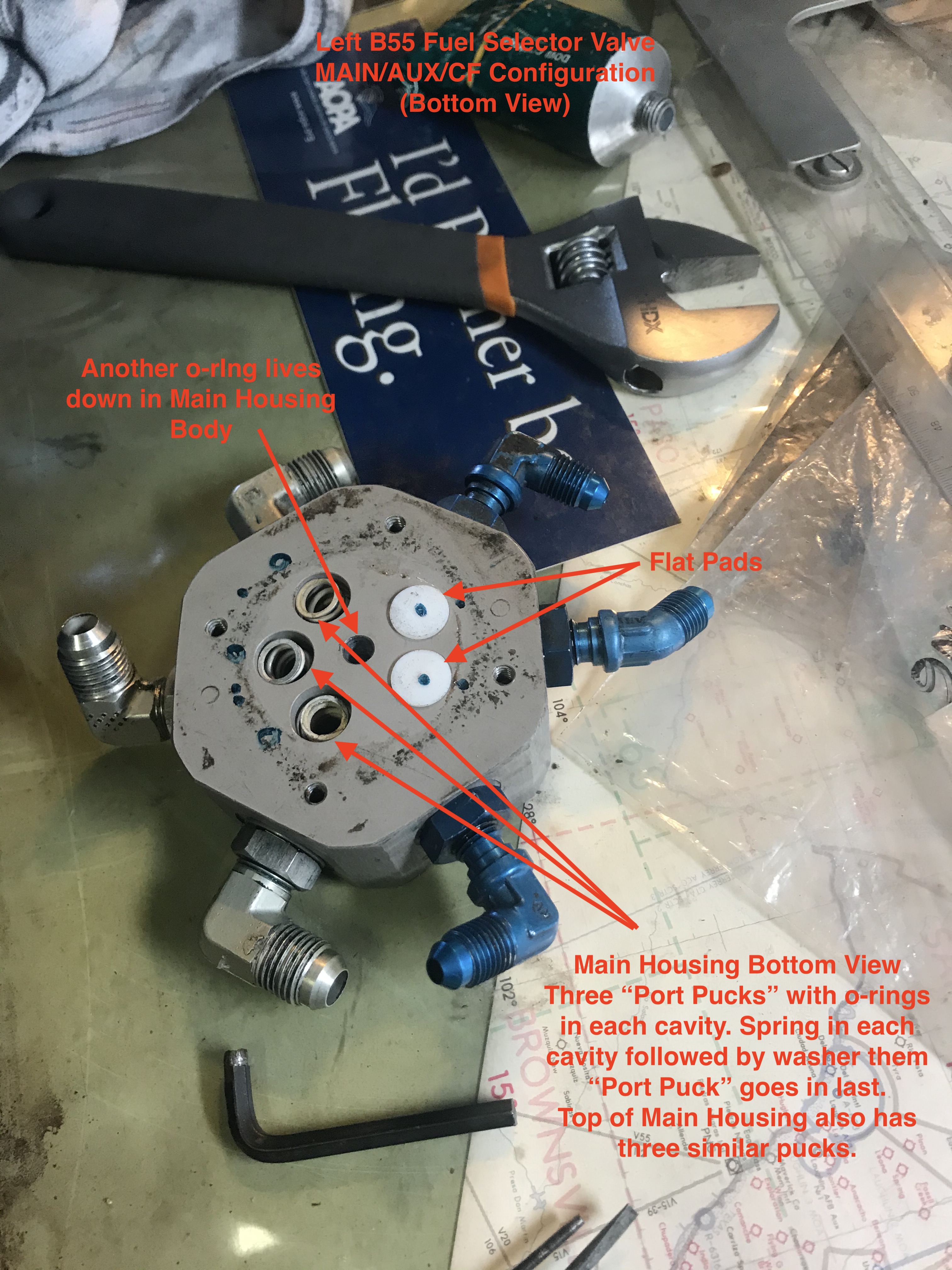

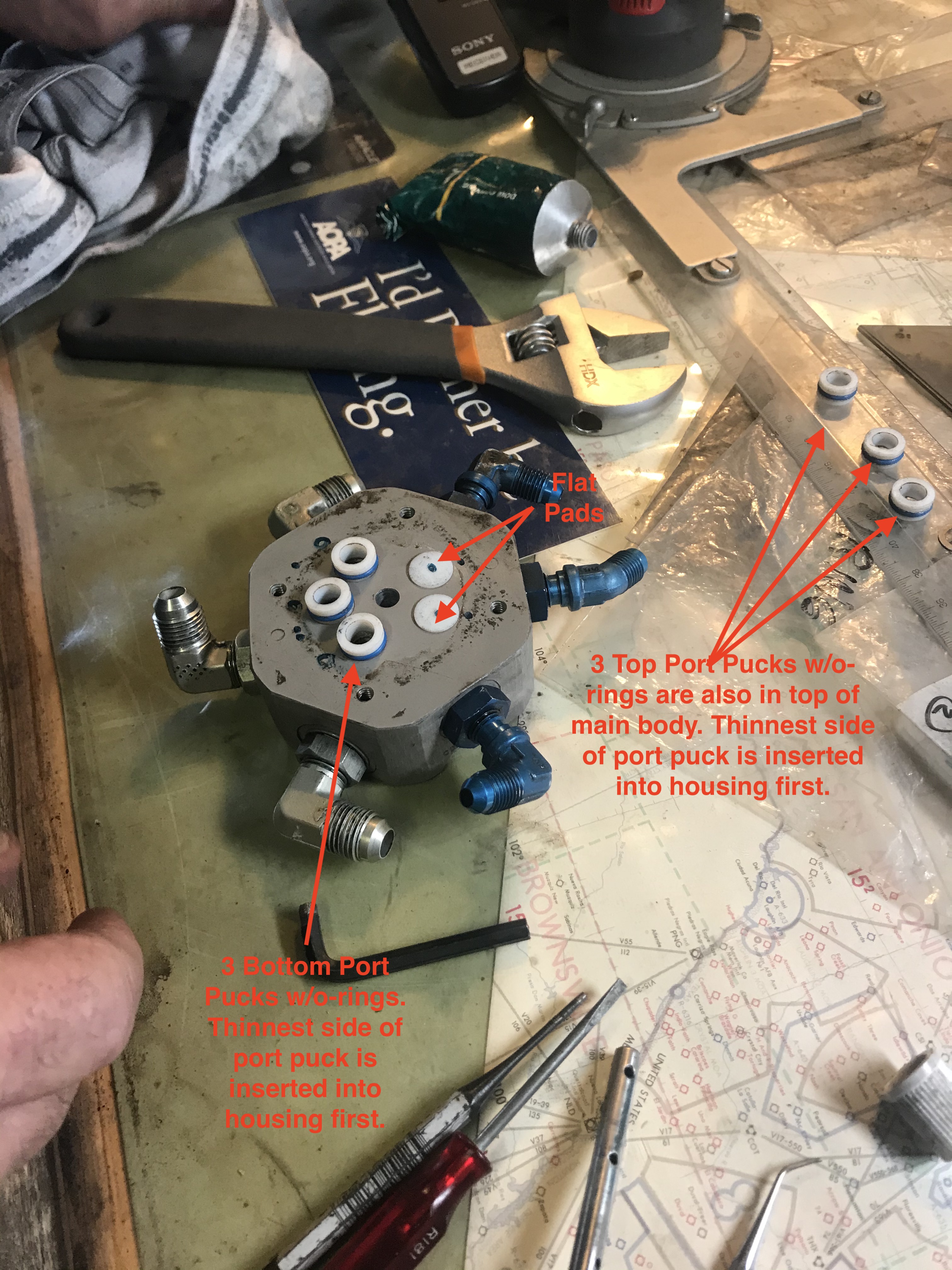

Hopefully, the

below narrative and high resolution images can take some of the intimidation out

of the opening up of one of these beasts by a qualified A&P mechanic.

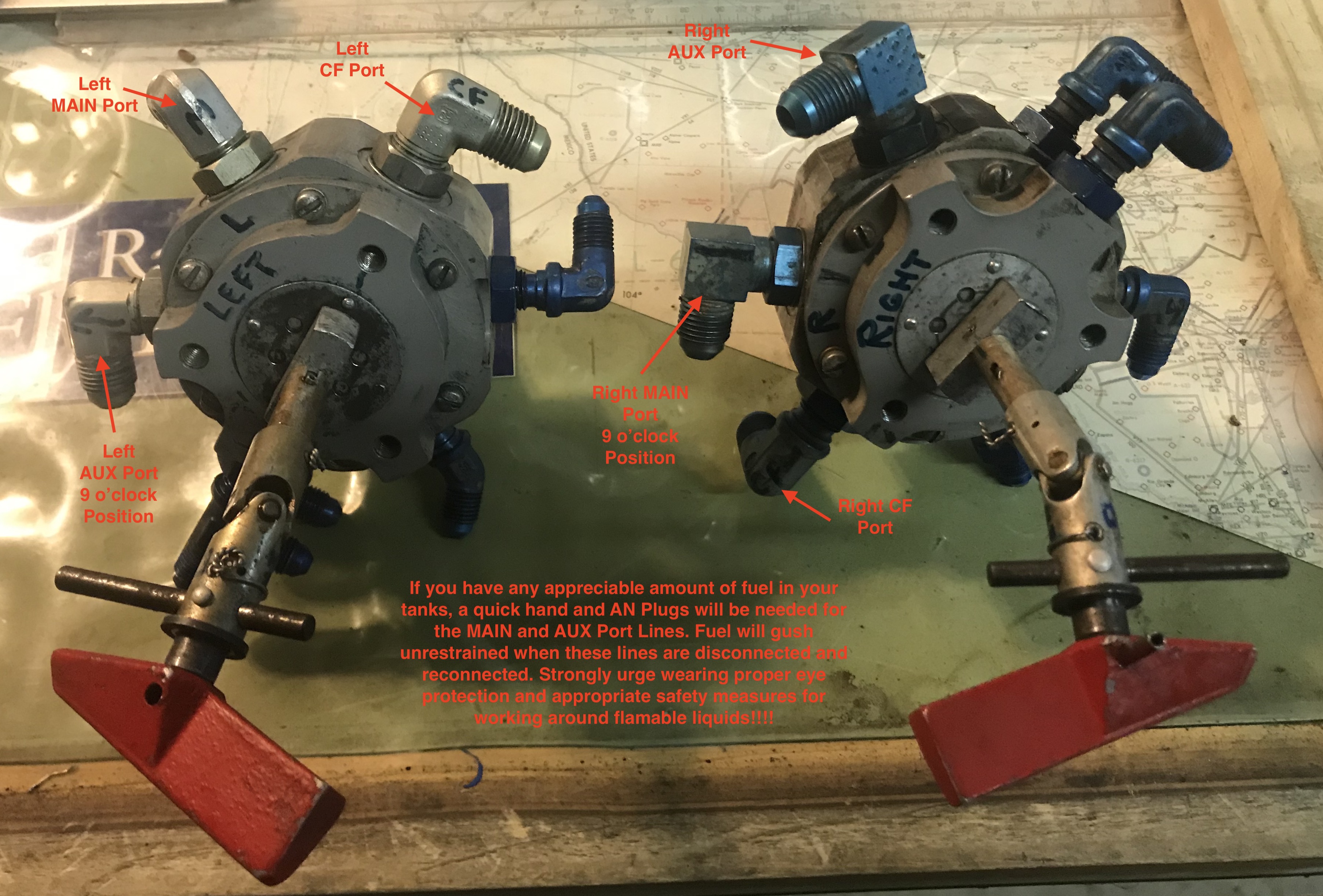

The removal was tedious, especially with

nearly full tanks

, which

required AN plugs and a very quick hand on the MAIN and AUX feed lines going into the selector valve. , which

required AN plugs and a very quick hand on the MAIN and AUX feed lines going into the selector valve.

Unless you have some form of bent shaft or

selector body warping (highly unlikely), you're in luck, because a simple fix

might just be to replace the o-rings in the selector body.

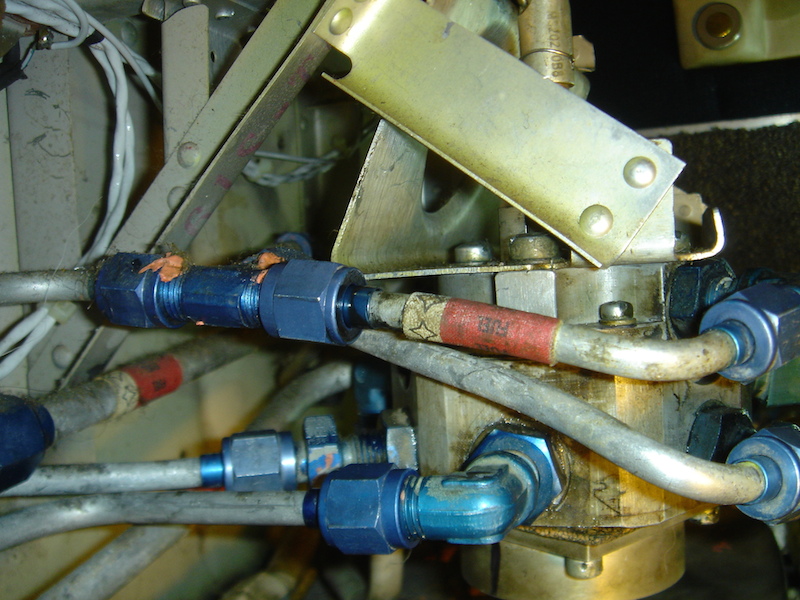

It's a rat's nest of

fuel lines in there and a not so great place to access (stubby 11/16" and 9/16"

wrenches were essential to me in this aspect) but it is doable to

extract these items from their home and open them up on the bench and replace

the o-rings.

Be sure you have the work done by an A&P/IA or are well supervised

by one, as this, like many areas of certified birds, is not an area for

unsupervised amateurs.

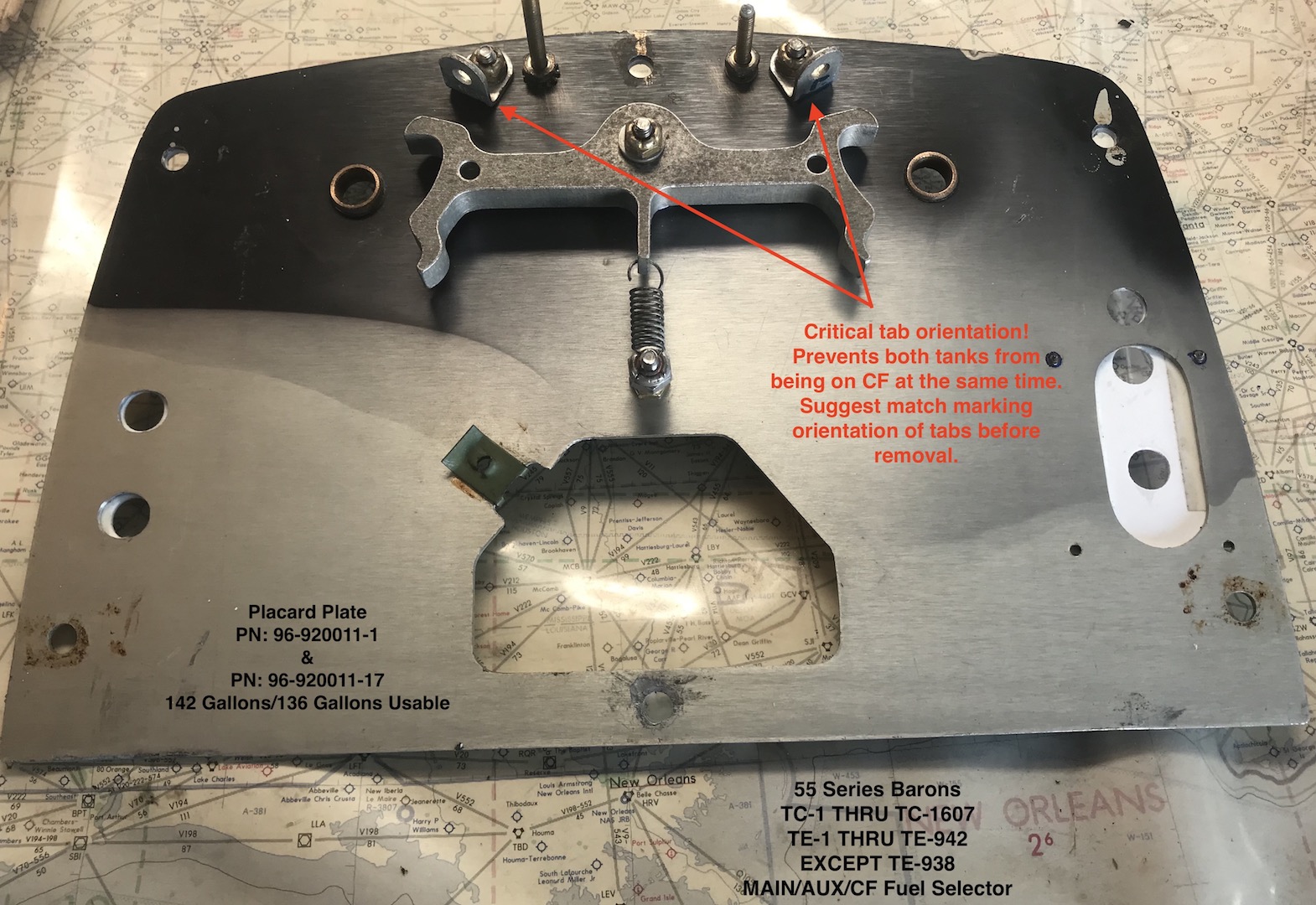

WARNING

It is

EXTREMELY CRITICAL that the orientation of these

components is

preserved for proper functionality!!!! My IA and I

match marked

and photographed everything to insure a proper

reassembly.

See the B55 MAIN/AUX/CF fuel selector parts extract

HERE for

o-ring details.

See a narrative

HERE written by

B58 owner and A&P, Larry O., on his B58 fuel selector R&R.

See

HERE for some flurosilicone o-ring options for the shaft and body o-rings if

your A&P will authorize a substitution. Flurosilicone o-rings have been shown to

deliver much greater service life than their 1940's nitrile rubber versions.

An IA/Bo Owner (Bob B.) reminds me that the so

called "o-rings" in the fuel line fittings attached to the selector body are in

fact "BOSS SEALS" (Item #26 MS29512-6 in the above fuel selector extract)

and are different dimensionally AND in chemical resistance than conventional o-rings.

He says:

"They have a cross section almost square. MS 28778-xx (in the case of my B55,

MS29512-6). They are a different hardness/durometer than an o-ring also. The

size is a reference to the tubing size for the affected fitting. Thus a -6 is

for a 3/8 fitting which is for most Beechcraft fuel selectors. O-rings are sized

by cross section diameter and inside diameter and classed as fuel or oil. It is

not unusual for mechanics (ought to know better) to assume a 'standard' o-ring

is used. In a way that is correct if one uses 'standard' in reference to the

correct part for the application. This is the Readers Digest version of the

Parker Handbook.

The IPC calls them o-rings, yes. Thus the confusion by

many to use a 'standard' o-ring. The part number MS29512-xx uses a number '4' or

'6' to indicate tube size. It is a tube fitting in the Mil Spec and fuel

resistant, very important distinctions. This is why using the parts manual is

usually the best source for part identification.

Many of us (A&Ps) learned to use the part needing the

o-ring to determine what to order-Measure the cross section, measure the

diameter, look it up on a chart. I have a 20+ year old chart. It gives an

explanation of the applicability for the part numbers and calls the AN & MS

(o-rings) - Boss Gaskets.

MS29512, MILITARY STANDARD: PACKING, PREFORMED,

HYDROCARBON FUEL RESISTANT, TUBE FITTING, "O" RING (01-SEP-1965) [S/S BY

SAE-AS29512].

Not really a tomato-tomato issue. but this is one of

many things that come up the industry will never truly eliminate. When I was in

Corona, only a mile from Aircraft Spruce, this very issue caused a great deal of

heartburn with their parts department. The boys in back packed the o-rings in a

baggy and I refused them. The actual single packages give lot, expiration date,

and clear identification. You can not tell the difference between a MS29513 and

a MS 28775 the same size but one is fuel and the other oil. Although I have seen

them used interchangeably, it is not BEST practice. Many parts are commonly

called by the Brand name regardless of actual manufacturer-Sheet metal screws

called PKs for instance."

"A rose by any other name would smell as sweet"

So be careful not to just replace these BOSS

GASKETS with a

conventional o-ring that looks like it fits!

But anyway, for those who insist,

HERE is a link to a

sizing chart for the MS29512 "boss gaskets" in case you want to "roll your own

in M25988/1-XXX Flurosilicone".

Be sure to secure A&P approval prior to any

O-ring substitution and return to service!

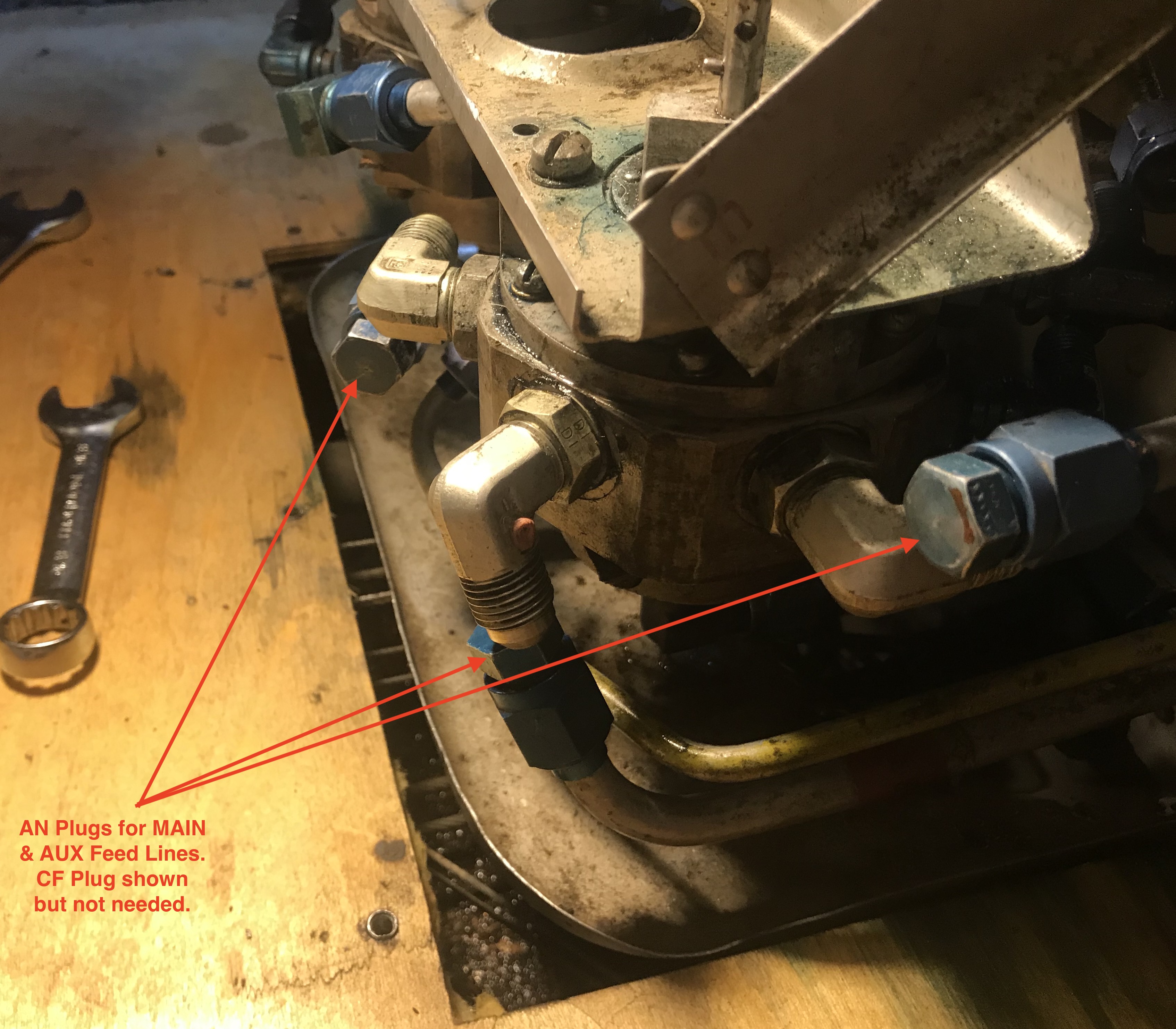

Below is the rat's nest of fuel lines for the

B55 fuel selector that

you'll be looking at:

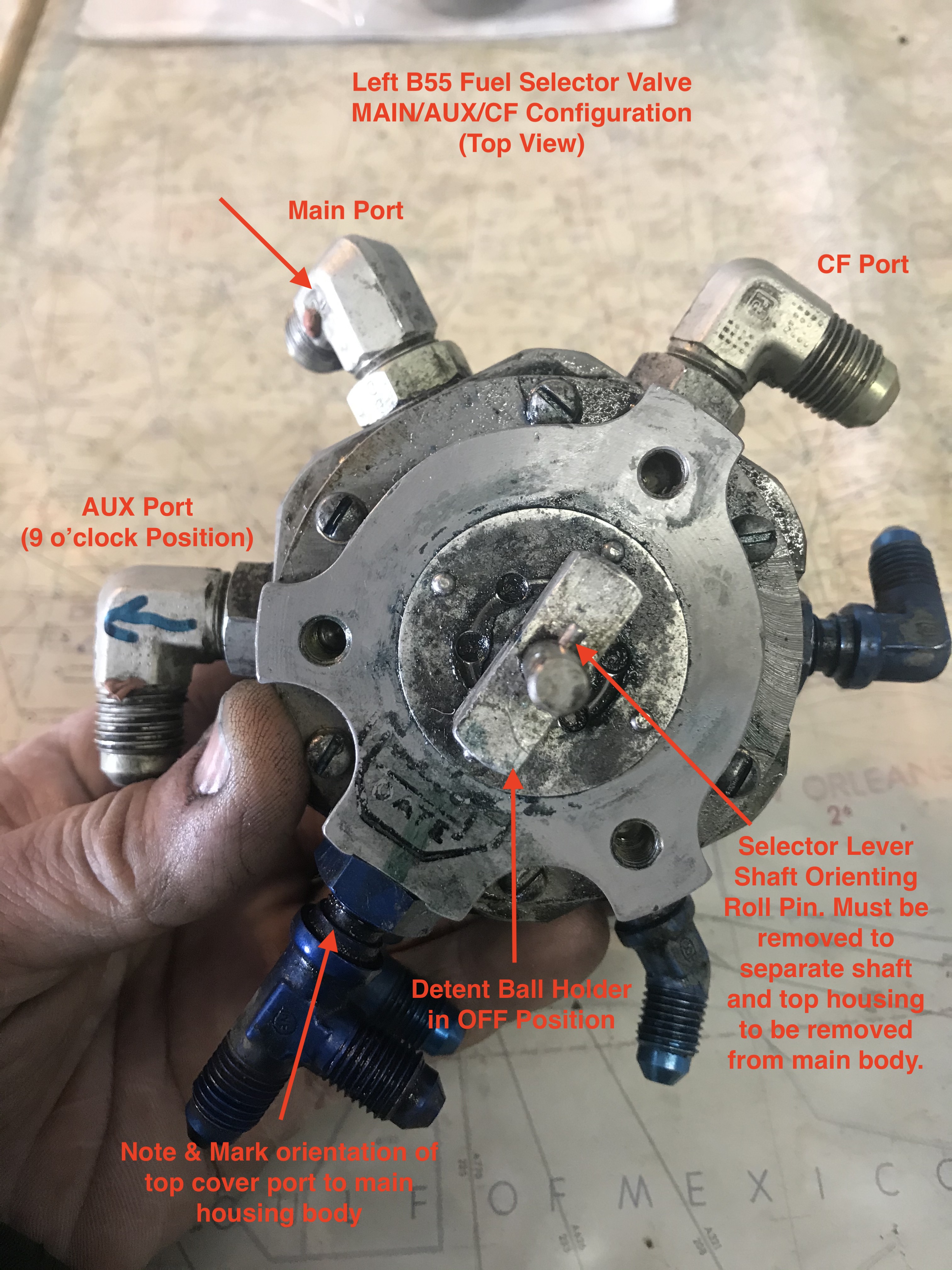

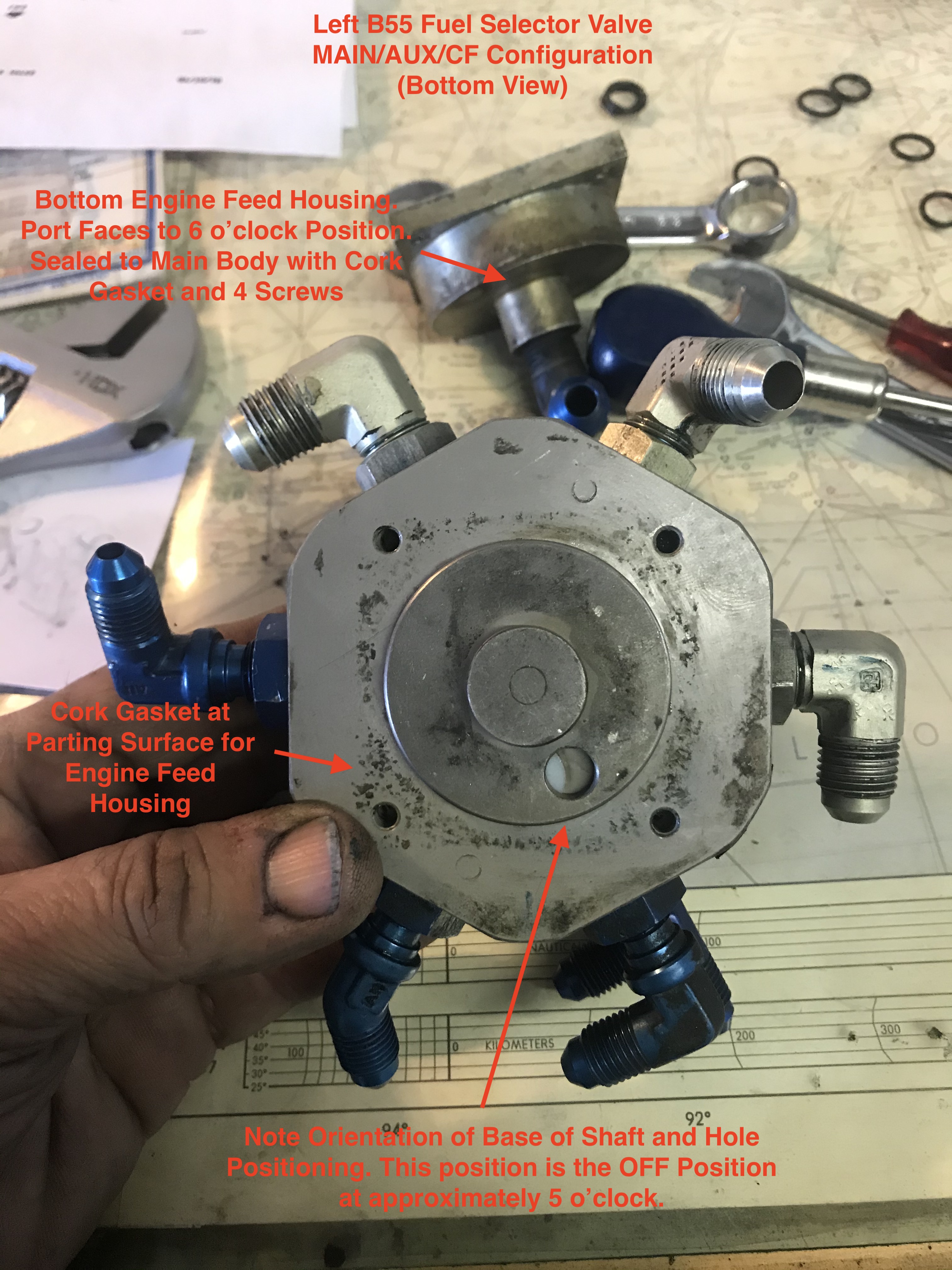

Be sure to put whatever markings, tags or

numbers you feel are needed to get EVERYTHING back in the same orientation! THIS

IS ABSOLUTELY CRUCIAL! Digital

photos are also a big help.

Tips I learned:

1. Have proper size AN plugs on hand (and be

quick of hand to insert plugs) for MAIN and AUX lines or drain fuel tank(s).

2. Wear appropriate eye protection with splash

guards.

3. Match Mark and/or photograph all parts and

their orientation to each other. Starting with both valves in the OFF position

was helpful in a baseline orientation and prevented fuel from also coming out of

the engine feed port at the bottom of the valve.

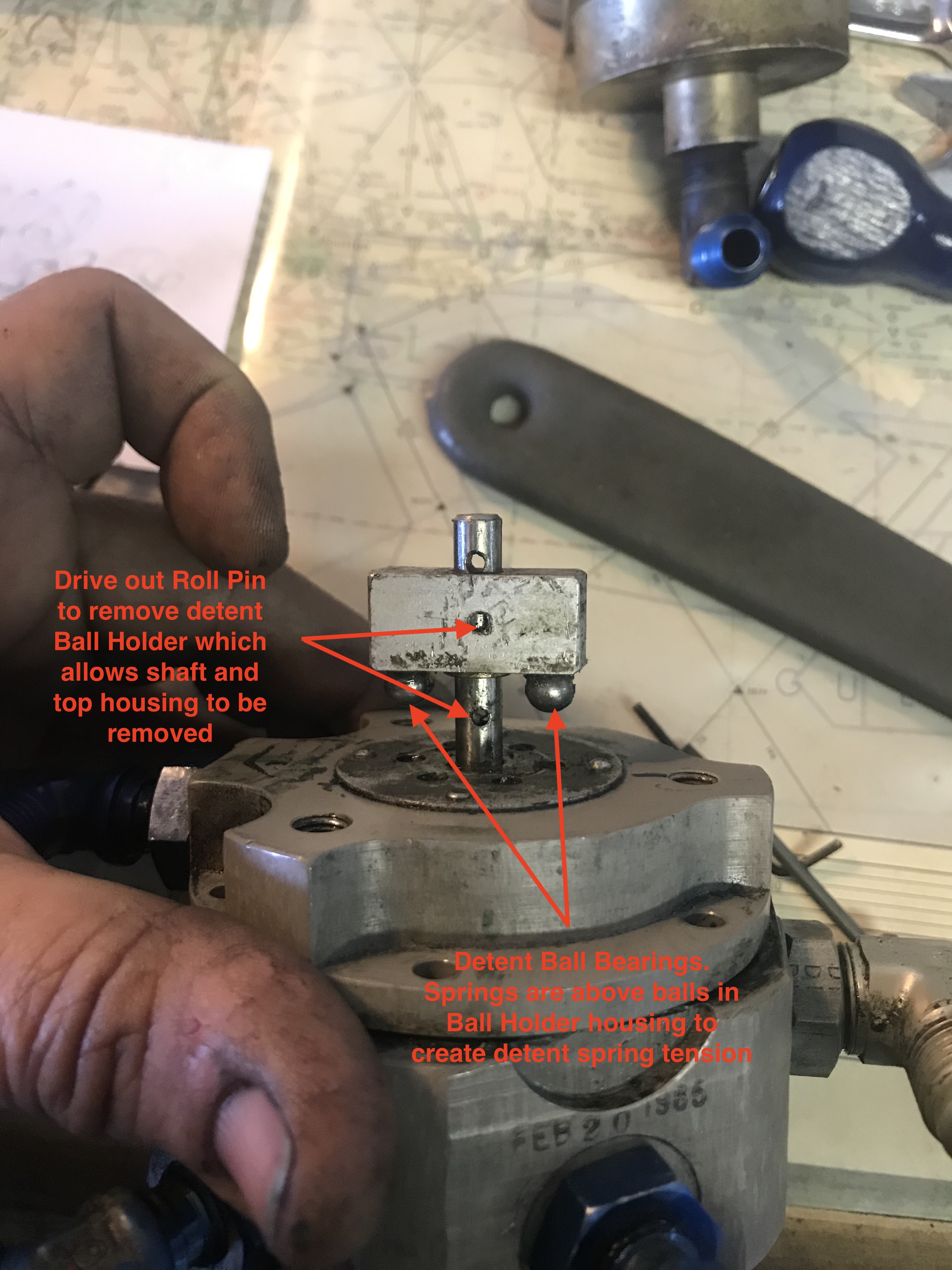

4. Beware of burrs induced in center shaft

(which can damage interior o-rings) as a result of driving roll pins out (a rat

tail file can deal nicely with these).

5. Leaving top mount screws in mounting frame

aids in loosening lines to valve.

6. Allowing valve to "float" upon

re-installation, without the top three mounting frame screws attached to

mounting frame, aids in attaching lines to valve.

7. Match mark fitting orientations to enable

proper line orientation and ease of reattachment.

8. Upon final tightening of each line apply

torque putty to identify it as a torqued line.

9. Count the number of fittings on each valve

and confirm that the total matches the number of lines that have torque putty

applied

10. Leave left selector valve out to remove

right fuel selector which allows easier access to MAIN/AUX/CF lines on left side

of the right valve. Re-install right selector valve first

11. Right selector valve is of similar design

but orientation of lines and shaft positioning is different. AGAIN, match

mark/photo everything related to orientation of the valve body housing, center

shaft and port fittings.

Another watch out is to be sure to use some form of

Torque Putty or marker pen or indicator to indicate that you final tightened each line.

This

will help you confirm that all fittings have been properly tightened.

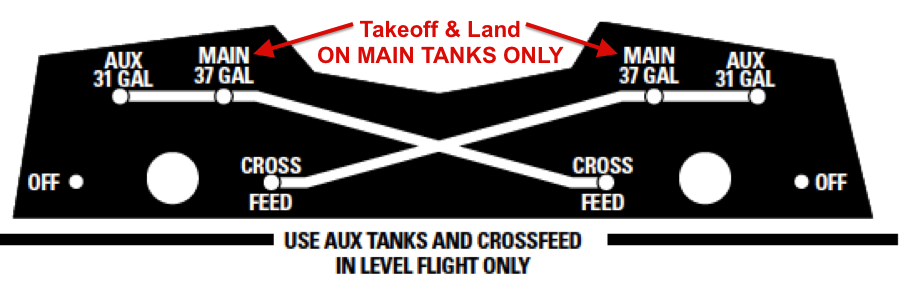

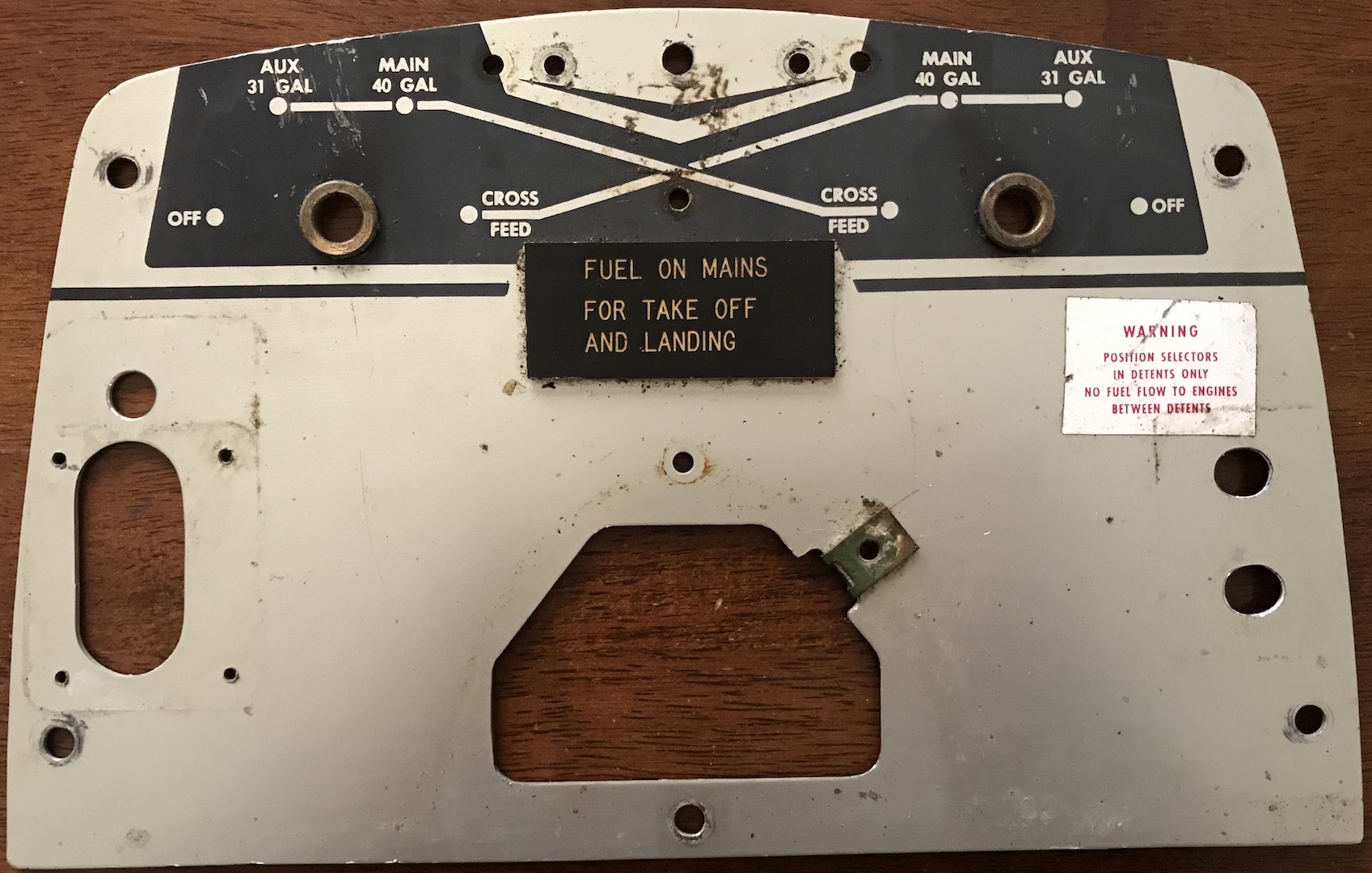

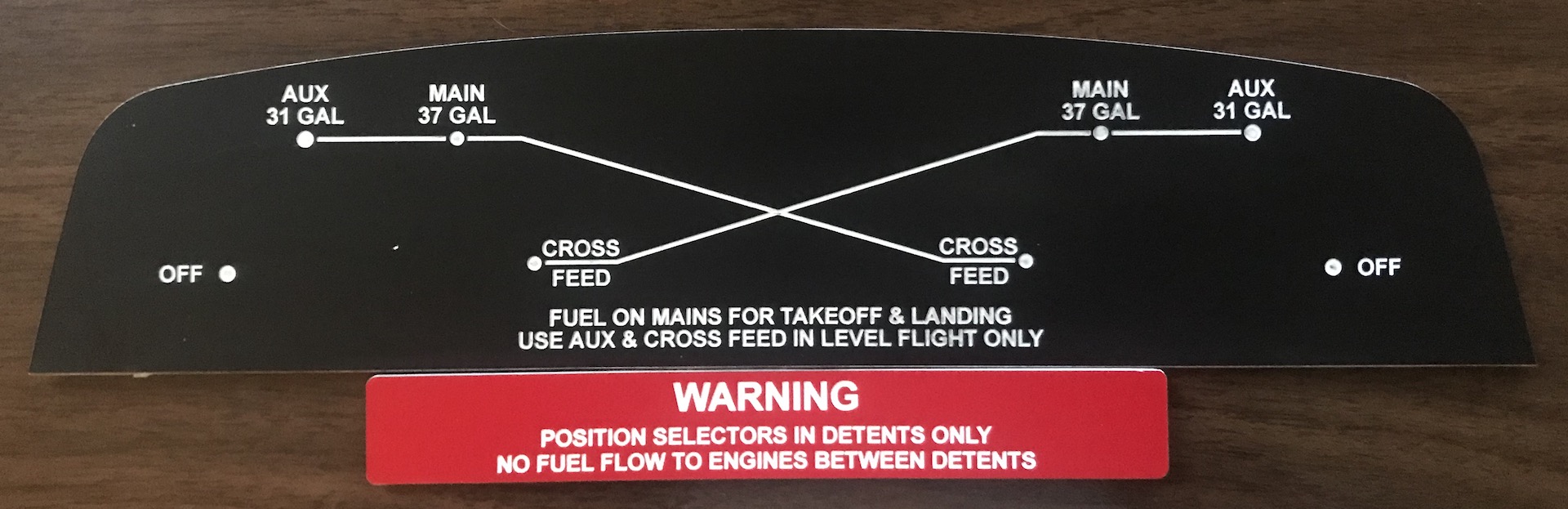

Baron 55

Fuel Selector Cover Placard Makeover

~TC-191 THRU

TC-1607

TE-1 THRU

TE-942 (Except TE-938)

Since you've made it this far in the B55 Fuel

Selector Valve narrative, you might be interested in buying an extremely custom

set of placards to freshen up your fuel selector cover panel.

If you're diving into your fuel selector

valves for o-ring replacements and your 50 year old cover plate has seen better

days, you might like to give it a fresh look.

Check out the before and after pics of how my

custom placard design came out and click the PayPal Buy It Now Button if you'd

like a set:

Before

After Replacement Placards

Cover Plate Backside View

For $95 (includes FREE USPS

Priority Mail US Shipping), you will receive the full width top main selector

valve roadmap placard and the red "WARNING" placard (as shown below) that sits below.

It does NOT include the

intercom placards since these may or may not be how your cover is configured for

your intercom setup.

The 37 gallon Main marking is

in compliance with the latest POH published limitations (all us 55-Series

drivers know it is a 40 gallon tank but 3 gallons became legally deemed unusable

in later years).

Applicable ONLY to the

following 142 Gallon/136 Gallon Usable SNs:

~TC-191 THRU

TC-1607

TE-1 THRU

TE-942 (Except TE-938)

NOTE: Using the existing cover

plate as a template, you will need to drill your own holes in the large main

placard to insure that the placard fits your exact fuel selector cover and any

post lights that are in your original cover. The large holes for the selector

valve shaft bushings are approximately 11/16" and are easily done with a step

drill like

THIS.

Your purchase also helps to

supports the CSOBeech.com site.

This placard will NOT fit Early 95-55 Models with a fuel selector as shown

below. It is believed that the 95-55 Aircraft are SN: TC-1 thru TC-190.

As always, if you have no idea what a fuel

selector or an O-ring

is or what a good one is supposed to look like or what a bad one looks like,

close this browser page and ask your A&P licensed mechanic to have a look at

your fuel selectors and let you know if they are leaking.

If

this narrative has helped you, please

donate to keep CSOBeech.com Free

|