Are your Beechcraft wing landing lenses cracked, cloudy or warped from those

high amp draw incandescent bulbs? Well, what are you waiting for? Here is a

narrative that will help you in tackling this cosmetic improvement of your

Baron, Bonanza, Debonair or Travel Air.

I've used the GLAP's lenses for both my landing light covers on the wings.

Their fit and finish was excellent when I changed my lenses a few years ago. The

price back then was a bit lower too....

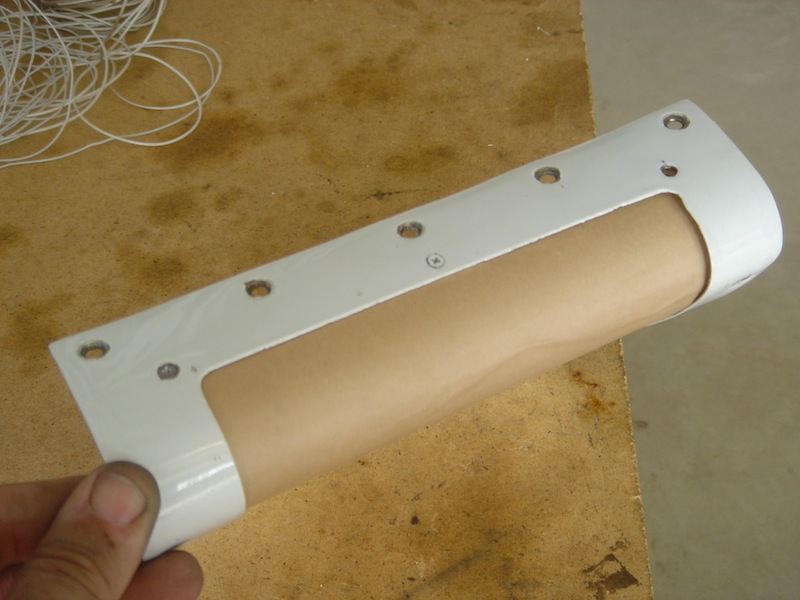

Here are a few pictures of fitting the lens into the outer frame

This is a tedious install because not only do you have to drill the holes

into the new lens for the frame but you have to trim the edges after you get it

into the frame to fit the hand made opening in the wing cavity. It would appear

every opening is a custom fit.

I very carefully used a belt sander on my edges to get the wing opening fit

correct after I had the holes drilled for the lens to fit the frame. Leaving the

protective film in place on the lens worked well for me.

Also, don't forget to use an acrylic drill bit or one modified to drill

acrylic so that you do not introduce a stress crack into the hole that will

crack at a later date.

HERE

are some great trimming/drilling instructions from Great Lakes.

No more melted lenses for this guy with the low amp draw and low heat

generating HID technology. See many HID and LED bulb options for your Beechcraft

HERE

Of course, your methods may vary and be sure to have your A&P check your

work.

Here is John S.'s DIY method for making his own wing lens from 0.100" Lexan

or acrylic sheet:

0.100" Lexan, used plaster cast of original lens to mold lens in oven,

between 360-380*F. Cut with thin blade on die grinder, used flapper wheel on sander to fine fit

and get rid of melted edges. I’d recommend Dremel tool with tiny burr to make precise hole,

then enlarge with cone shaped sanding head (bought as a package pair at Walmart)

to enlarge hole to allow for "fudge factor" in fitting. Tried heat gun

and got irregular

bending and bubbles in Lexan (polycarbonate). Oven is very slow but sheet will slowly drape over mold.

Click HERE for a movie of

his finished result.