|

After a happy Meet & Greet with many

Beechcraft owners on Saturday November 8th, at Bridgeport, TX (KXBP) to

celebrate <$3.00/gallon fuel prices, Ed and Marcia L. continued on their way in

their A36 Bonanza, uneventfully, to Ardmore, OK.

Here's Ed, in the khaki trousers, topping off his bird.

Their return south a few days later was

anything but uneventful.

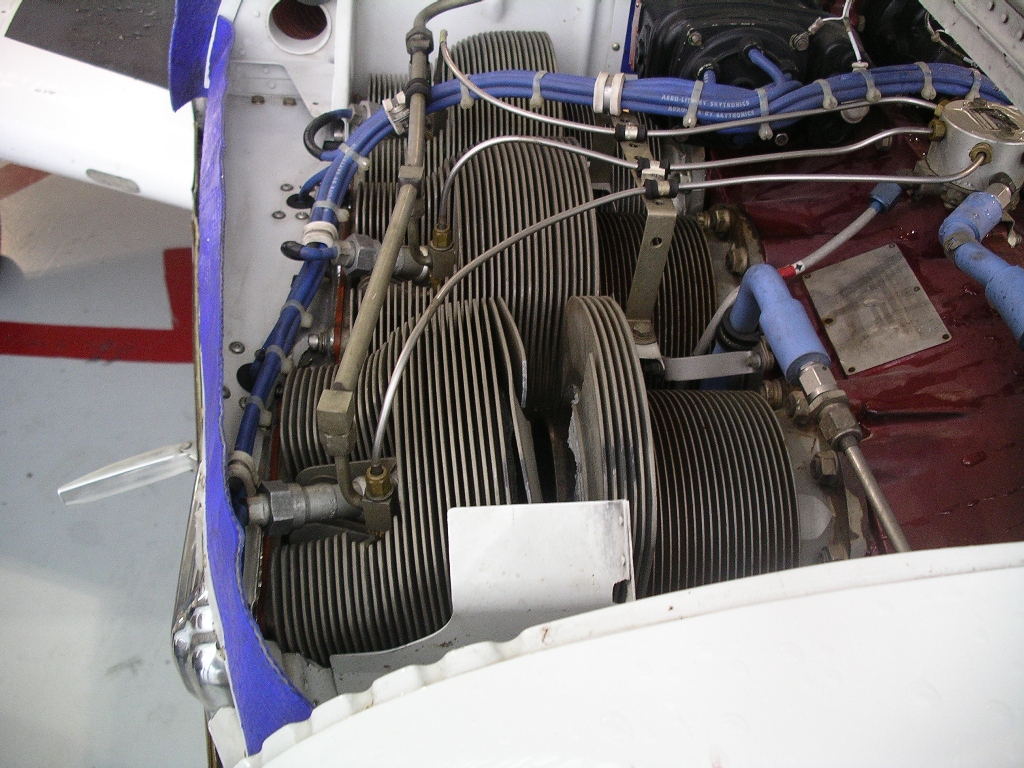

Imagine this happening to one

of your cylinders in-flight! On second thought, let's not!

Here is Ed's account of what happened:

We had the dreaded "uh-oh" Sunday after we departed from

Ardmore, OK, and headed down to the north Dallas area. At 4,500, and at

relatively moderate power, our engine cratered. We later found the number 5

cylinder head blew off, disconnected. There was a "bang", the engine immediately

ran rough, and the JPI confirmed power loss in the cylinder. Of course, while in

the air, we had no idea what had happened, but I sort of reckoned it was a

cylinder coming apart. We have ECi cylinders. There's an AD out on the subject,

though it doesn't appear to cover our specific cylinders.

Marcia pushed the GPS "nearest" button to locate the nearest

airport, which fortunately turned out to be Gainesville, TX (GLE). We were on

Center frequency, declared an "emergency" and stayed with them for a couple

minutes until we identified GLE, then we switched to GLE Unicom, again declared

an emergency asking everyone to stay clear because we were coming in with only

limited power. The engine was still running, but we had plenty of altitude and

we didn't want to push the power issue. There was a clunking noise.

Our altitude was just fine for the 6.5 nm coast to GLE, and we

entered onto base, then turned final, and landed quite normally. The engine

provided taxi power to get us to the tie down. We shut it down normally.

Once on the ground, we opened the cowl to find #5 cracked all

the way around about 5 fins up from the bottom of the louvers. It had separated

by about a third of an inch.

Rick, the airport guy at GLE, was very nice, and a number of

other pilots who had heard our call, landed to check on us. There wasn't much to

do on Sunday, so we made plans to spend the night and get into it Monday

morning.

I did call George Braly on his cell after we landed. George as

usual was calming and reassuring. We knew from the moment we saw the injury that

we'd turn the final repair over to Tornado Alley, George and Tim Roehl.

The next day, we visited Bill Morrow at Tomlinson Aviation at

GLE and his maintenance supervisor Tim Fellegy. Tomlinson is a large and

impressive shop on the field. They pulled the plane inside and everyone gathered

around as we opened the cowl again for show and tell. Upon seeing the rupture, 3

of the guys said kinda in unison, "do you have ECi cylinders?" We confirmed that

we did.

Tomlinson removed the broken cylinder. The good news is that

the rings were still attached to the piston, and piston and rings do not appear

damaged. We don't believe any metal invaded the remainder of the engine.

Tomlinson will be checking closely for that.

Tim Roehl coordinated with Tomlinson, volunteered to ship a

serviceable cylinder and parts to Tomlinson which arrived today. Once it's

installed, and the engine is serviceable, TAT will ferry N29959 to Ada where it

will undergo a top overall, installing new cylinders the TAT way. They'll be

Millenniums, new design and manufacture. We've had issues with the old cylinders

since they were installed by Ultimate in 2001, and we've decided to put the

issue behind us once and for all.

We're very impressed with the helpful manner of the folks at

GLE, at Tomlinson and Tornado Alley. We should have N29959 back in the air in

about 2 weeks. Our pocketbook will be a bit lighter, but we are fortunate to

have been forced down at Gainesville, TX, where there was a fine shop like

Tomlinson, to have no further damage or injury, and to have our great friends in

Ada resolve this matter.

Ed reports that these cylinders were not the

subject of any current AD on ECi cylinders. The mechanics involved in the

cylinder removal will be making appropriate agency reports on this cylinder

failure.

Here is another ECi cylinder

failure from a Canadian crash of an O-360 equipped experimental Glastar

aircraft.

TSB Final Report

A09P0156—Engine Power Loss-Forced Landing

On June 12, 2009, an amateur-built Glastar was on a recreational

flight from Yellowknife, N.W.T., to Kelowna, B.C., with two pilots on

board. At approximately 14:01 Pacific Daylight Time (PDT), shortly after

passing Chetwynd, B.C., a severe powerplant vibration and loss of power

was experienced. The engine power was reduced to 1 000 RPM and a forced

landing into a field was attempted. On short final, the aircraft struck

a power line and veered off course to the right, where it struck trees

and rising terrain. The pilot in the left seat received non-life

threatening injuries. The pilot in the right seat was fatally injured.

There was no emergency locator transmitter (ELT) signal and no fire. The

switch on the ELT was found in the OFF position.

Examination of the wreckage revealed that the No. 2 cylinder head had

separated from the base (see Photo 1) and the crankshaft was

severed at the propeller flange. The engine had 212 hr total time since

new (TTSN) when the failure occurred.

Read the whole article

HERE

NEWS FLASH:

27 February 2012 NTSB Safety Recommendation on ECi Cylinders

HERE

Here is another ECi cylinder

failure in March 2015 from Bonanza owner Stephen B., of California, in an

IO550 TN aircraft.

In March 2015, Stephen reports 115 Hrs SNEW ECi Cylinders were

installed, See the whole

BeechTalk thread

on this near in-flight engine disaster

HERE.

An investigation by industry engine gurus is underway.

Here are some additional items to peruse on this topic:

Check out this highly illustrated

FILE .

And this

FILE: 'ECi Cylinder Head Failures on Continental IO 520 & 550 Engines" a

briefing presentation for Dorenda Baker, FAA Director Aircraft Certification

Service.

Page 4 of the above file: "The ECi failure rate is 32 times

higher than Continental’s"

Far be it from me to project any conclusions, it's just the

data that's out there.

|