Well I decided to make the switch to Desser as my GY Flight Custom IIIs were

wearing. My plan was to pull them off while in good shape, replace them with new

GYFCIIIs and have the casings retreaded by Desser so they would be standing by

when the current/new tires wore out.

The old tires were in great shape, still some tread remaining above the

groves, no flat spots, no ply showing, no vibration, no obvious defects, and no

weather checking. I hanger my plane religiously so the tires are NEVER in the

sun. My A&P and AI thought I was pulling them off at least a year early but I

wanted to make sure they were in good enough shape to retread. Was dismayed to

learn the cheapest shipping would be $80 but bit the bullet and sent them.

A few weeks later I get a very short email from Desser saying they could not

complete the retreads and the casings were condemned, but they would be happy to

send me other retreads at $306 each! Iíve been working with them to find out

what happened and have been getting different stories. It sounds like they

retreaded the casings but when they did the final inspection the x-ray (or

whatever passes for it) showed some delamination (in both tires!). Itís not

clear whether this was in my casings, or in the new material.

So the downside to sending your cores for retread is that youíre out the

significant shipping cost if it doesnít go as planned. Itís pretty

disappointing. Wonít try that again, and certainly wonít recommend it unless

someone lives close to Desser and they can avoid the shipping cost.

Jim A. 9/21/2019

Another Retread Source That

Receives Positive Pireps

On 9/21/2019, a 6x6-8ply is reported to be $70!

Here are videos of my gear swings with Desser

retreads at all three positions. No rubbing or airframe clearance issues

Video 1

Video 2

Video 1

Video 2

Read the Aviation Consumer 2008 Test Results

HERE

Read the Goodyear Tire Data

HERE

Read the Goodyear Tire Maintenance Manual

HERE

Read the Michelin Tire Tech Data

HERE

PS: Beech Talker, Rick O., was at a Michelin

presentation in which the rep stated that inflation of 90% to 105% is considered

"acceptable operating parameters". Anything less than 80% is considered a "FLAT

TIRE"! SO please regularly check your tire pressures, especially around the

change of seasons and when you traverse temperature zones in the country. When

Rick asked about high quality retreads, the Michelin rep stated that Michelin

recaps were better than their new tires!

Here's the Aviation Consumer 2008 Test Results

Narrative:

By Joseph (Jeb) Burnside and Martin Schneider

While car tires are all about the

finer points of traction and resistance to hydroplaning, the best we can hope

for with airplane tires is that theyíll make it through a couple of annuals.

To do that, they need a lot of tread depth, the right rubber compound and a

pilot whose idea of making the first turnoff doesnít involve landing with the

brakes locked.

Heat is hard on tires, but landings chew up the

rubber so to find out which tire is top dog, we conducted the second Great

Florida Tire Death Match, subjecting each of 11 new tires to 300 blistering,

rubber-burning simulated touchdowns on a flat stretch of I-75. Conclusion?

He with the most tread wins, and that would be the Goodyear Flight Custom III.

In this case, "wins" means

delivers the most landings for the moneyóin

other words, the best value. But that doesnít mean

the most expensive tire is always the best choice for every owner. More on that

later, but first, on to the tests.

Do Over

If most of your flying is from A to

B, you probably donít do many landings, even if each "landing" might

be labeled a series of controlled collisions. For many owners, tire replacement

is more about ageó

weather-related cracking, for exampleóthan

it is tread wear. Still, smearing rubber on the runway is what itís all about

so we dug out our test rig, mounted it on the trailer, bought a sample of most

6.00 X 6 new tires and tubes and got busy.

As shown here, the rig consists of a

pneumatically operated pivoting arm mounted on a

utility trailer towed by a pickup truck. The arm is activated by a valveócall

it an air-powered gear selectoróthat

reasonably simulates a retractable gear airplane by allowing a tire touchdown

and retraction about every six seconds.

When we conducted these tests four years ago, we simulated 200 landings, but

this time we upped the ante to 300, albeit with a slightly lighter weight load

on the trailer. We also skipped the skid destruction test, which involved a

mounted wheel and tire touched down at 30 MPH on a closed runway. We wanted to

know how the tires dealt with this abuse. Some did, some didnít.

Of the 11 tires tested in 2004, we rated six as unserviceable after the skid

test. There wasnít much to gain from repeating it this year, so for our 2008

edition, we substituted a two-mile taxi test at 30 MPH to test heat buildup. We

measured the tiresí temperature before and after the taxi test and from there,

we went right into the simulated landings. We also simulated a faster landing,

at between 65 and 70 MPH, instead of 55 MPH or so in 2004. We chose this speed

to better approximate the 60-knot

touchdown many tires see in actual use.

Metrics

We weighed and measured each tire before

and after the tests. In addition to tread depth, we measured diameter, finding

that most tires are less than 1/8-inch out-of-round.

As one might expect, the less expensive tires displayed the greatest

variation; premium tires from their respective manufacturers exhibited better

quality control with regard to roundness. Goodyearís Flight Custom, for

example, was spot on for roundness, as was the Michelin Aviator. The inexpensive

Specialty Aero Trainer, Condor and Super Hawk were at least 1/16-inch out of

round.

Weight varied, too, with the less expensive

tires generally being the lightest, given that their construction uses less

steel, fabric and/or rubber. Goodyearís top-rated Flight Custom III was the

heaviest tire, at 11 pounds, 4 ounces, followed by Desserís massive Monster

retread at 11 pounds. The lightweight was Specialtyís Aero Trainer at 6

pounds, 13 ounces.

Rubber hardness can be a predictor of tire

durability, although in the end, we think tread depth trumps all.

We measured hardness with an analog durometer at

five points along each tiresís tread. Interestingly, we found that hardness

often varied from point to point along the treadís circumference and from

shoulder to shoulder. Again, you get what you pay for. The cheaper tires seemed

to vary in hardness while the premium products were more consistent.

Prior to hitting the road, we marked each

tireís sidewall into eight segments and using a digital depth gauge, we

measured groove depth at each segment mark at the beginning and end of each

test. Although the tires vary in number of grooves, to make things simple, we

used only wear data from the two center grooves, averaging the 16 values for an

overall wear indication. No surprise that the data showed

the centers of the tires wore more than the outer grooves.

Hot Stuff

As noted in our previous report, heat

is hard on tires and we were surprised how much variability in heat rise we

recorded during the two-mile taxi test. While the Goodyear Flight Custom III ran

the coolest, some of the least expensive tires were right behind it, such as the

Condor and the Super Hawk. Desserís Monster and the Specialty Air Hawk ran the

hottest, as shown in the chart at left.

We also recorded before and after temperature

rise during the 300-landing cycle test. Here, the cheaper tires acquitted

themselves well, with the bargain $45.95 Aero Trainer tire showing a scant

2.3-degree rise. The Desser Monster and the premium Michelin Air topped the

scale in landing cycle heat rise, which while not a predictor of imminent

failure, is also not desirable, in our view.

To keep our observations consistent, we had

to park in the shade to prevent direct sunlight on the tire from contaminating

the data. For what itís worth, even in Floridaís weak February sun, solar

heat rise was so significant that we think tire covers might be worth the

investment to reduce heat and UV damage. As described in the sidebar at right,

our long-term weathering test showed that UV and heat really trash tires,

turning the soft rubber brittle and badly oxidizing the surfaces.

Test Findings

As we learned in our previous tests,

if a tire is landed frequently, durability is a function of tread depth and wear

rate. Deeper tread is a strong plus, but if the rubber wears rapidly, the tire

might not last as long as one with shallower tread but a lower wear rate. The

additional variable is price and this has the largest impact on

value. From most to least, the tread depth ratio in these new tires was 1.6 to

1, but the most-to-least cost ratio was more than 3 to 1.

To make some sense of cost versus tread versus

wear rate, we constructed a simple formula. First, we established a wear rate

for each tireóin

other words, how much comparative wear each tire showed per 300 landing cycles

related to its total tread depth. We

used this to roughly calculate how many

cycles the tire would theoretically deliver and we divided this number into the

discount price to determine a value ranking. The number itself is arbitrary; the

ranking is useful. Our intent was to answer several questions: Which is the best

tire for minimum wear? Which is best value tire? Are cheap tires a better buy

under any circumstances?

First, overall wear, irrespective of tread depth and cost. The top three here

are Goodyearís Flight Special, the Michelin Aviator and the bargain Super

Hawk, all of which had more than 95 percent of their tread remaining after the

test. Although this sounds good, hereís the problem:

Each of these tires started out with 20 percent less tread depth than the top

rated Goodyear Flight Custom and more than 30 percent less than Desserís

Monster.

When total tread depth is considered against

wear rate and cost, a different picture emerges. At the premium end of the

marketótires

in the $100 and up rangeóthe

Goodyear Flight Custom III tops the value equation because its .270 inch tread

depth exceeds its competitionómainly

its stablemate Flight Special and the Michelin productsóand

the price differences arenít that great between these tires. While itís true

that the Flight Custom had a slightly higher wear rate, it wasnít enough to

offset that generous tread depth.

At the lower end of the marketótires

under $100óthe

wear rate grouping and price relationships were scattered enough that the

Specialty Air Hawk came out as a winner largely because of an edge in total

tread depth. Cheaper tires such as the Condor, the Specialty Aero Trainer and

Air Trac didnít do as well becauseóyou

can see it comingóthey

started with less tread or they had a higher wear rate.

If there was a surprise for this round of

testing, it was the Monster retread. In our last test, we picked it as the top

value using a slightly different formula. But this time, its combination of a

slightly higher wear rate against the other tires and a higher price dropped it

from the top ranking.

This could have been related to more test cycles or the fact that the

simulated weight on the tire was lower. Also, the Monsterís rubber was among

the softest tested. Nonetheless, we still like the Monster as a good buy because

of its top ranked tread depthógood

protection against skids and lockups.

Recommendations

One caveat: Drawing take-it-to-bank

conclusions from what are actually very slim differences in actual tire wear

rates is problematical. But weíre comfortable making some general

recommendations.

Goodyearís Flight Custom III came out at the top of our cost vs. observed

tread wear equation for two simple reasons:

The tire simply starts with a deeper tread than most of its competition and the

wear rate is comparable. The only tire with more tread, Desserís Monster

retread, also features a slightly softer rubber compoundóyielding

a durometer value of 61, vs. the Goodyearís 63. Plus, the Flight Custom has

only two grooves, so it puts more rubber on the runway, thus reducing wear.

Specialty Tires of America (neť McCreary Tire and Rubber Company) came in

second and third with their Air Hawk and Aero Classic models, respectively. The

two tires started out with relatively deep tread and their rubber compoundóat

72, the hardest we testedókept

wear to a minimum. But it was low street prices that helped boost them to near

the top of the pack. The Air Hawk is a conventional four-rib tire while the Aero

Classic is designed for classic airplanes including warbirds, DC-3s and Beech

18s, according to the company, so it has a sidewall shoulder tread pattern

popular in the 1940s and 1950s. Itís designed for a particular look.

Michelinís premium Air model came in fourth

overall. Although we think itís a great tire, it suffers for lack of tread

depth and itís priced with the Flight Custom. Michelinís Aviator model had

much harder treadósecond

only to the Specialty Aero Classic and Air Hawkóbut

there wasnít enough of it. Despite wearing well, it finished near the bottom

of the pack in value, after Desserís Monster.

So, given the Flight Customís top-of-the-tire-pile

rating, is it automatically the best buy? Not necessarily. If you fly a lot, are

careful on the brakes and donít want to be bothered with tire changes, the

Flight Custom is our top choice. Itís

worth the $146 (discounted) asking price.

But if your airplane sits a lot exposed

to weatheróand

many airplanes doóyour

tires will probably rot before they wear out their tread. In this case, second

tier tires such as the Air Hawk and Michelin Air are good choices. We donít

recommend the cheaper tires at all, for two reasons: They start out with less

tread when new and given similar wear rates, the cost of changing them will

easily amount to a total higher than a more expensive tire would have in the

first place. Second, you need downside protection against a wheel lockup. We all

do this from time to time and if you lock a $51 Air Trac with .200 inch of

tread, itís toast. Do the same with a Flight Custom and you can might get

another year or two out of it. And in the end, thatís all we can ask of a

tire.

Here's what happens when you run with tires

that have thin tread remaining AND maybe land long or try to make that first

turnoff. Please folks, save your brakes and tires - go around and set it up

right or just roll to the end of the runway (pics courtesy of BeechTalker YS)......Just a thought.

As expensive as owning and operating our

aircraft is getting, I encourage all Beechcraft owners to take the opportunity

to evaluate lower cost tire options. Even finding NOS tires on Ebay can be a

good option to lower your operating cost on this consumable.

Here is an example of what happens when poor

airspeed control and touchdown point meet ~2,500' runway in a D55 Baron.

New Baron owners please note: You might need

something a little less than Blue Line over the fence and a touchdown point just

a little bit after "Brick #1" of the runway if you are intending to

land on a "short" runway. If you are not proficient in short

runway ops (my personal definition for a Baron short runway is anything less than about 3,000' or so), please get

some dual and sharpen up your game and save your airframe!

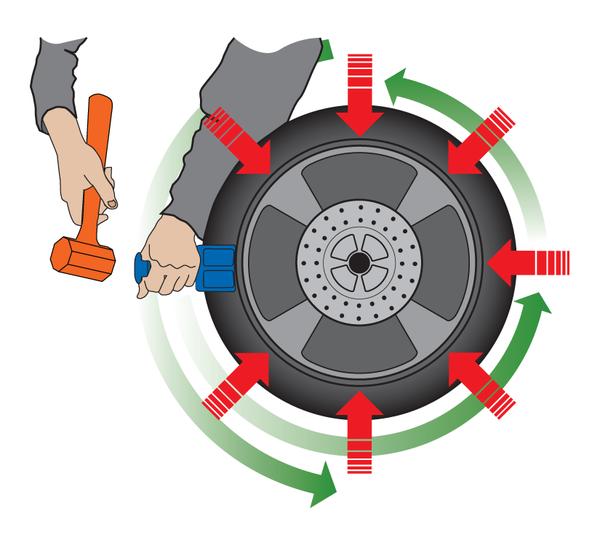

Amazing $20 CSOB Tire Bead

Breaking Tool (weighs 4oz)

Motion Pro Bead Popper

Bead breaking can be one of the more frustrating things that

owners can tackle in performing one of the FAA sanctioned owner maintenance

activities. This tool, weighing only 4 ounces, has gotten a rave review from

Beech Lister & fellow CSOB'er Greg G. of California.

Available from Motion-Pro

HERE

&

Amazon

HERE

Pirep and narrative contribution below, courtesy of CSOB'er

Greg G.

Before deciding to replace a couple tires myself I went looking for a tool to

break the damn bead grabbing the wheel... I'd tried replacing my nose tire

before and ended up carrying it to the FBO to get the old tire to let go of the

wheel.

I found this... for less than $20 at Amazon.com

Plastic, non scratching. Meant for dirt bikes. The manufacturer's web site

suggested using a dead weight mallet, ChiCom Freight had one cheap, less than

$10 for a 2.5# head. In a pinch I suspect a nice smooth 3# rock would do fine so

I won't bother putting that in the flight tool bag. If optimized for Beech

wheels it would undoubtedly have a different curvature of the wedgie business

end, but I thought it worth a try.

Finally used it on my 5.00-5 nose tire a couple days ago and on a main today.

Worked like a hot damn... tap tap all around, maybe a minute a side. No marks I

can see on the tire removed, certainly no marks on the wheels. Attacked a main

tire today, a 6.50-8 main first run FCIII that was fairly fresh when I bought

the plane... came off as easy as the nose tire, Am looking forward to finally

getting rid of the last natural rubber inner tube... the only tire that ever

needed airing on a regular basis.

I'm quite happy with the tool. YMMV.

Greg G. 7/6/2016

Here is a great tire protectant product

303

Aerospace Protectant that has gotten a great pirep from Jeff S., an A36 owner.

If your airplane is tied down outside you

might want to consider 303 for your tires and possibly interior panels, seating

surfaces and glareshields.

Safety Data Sheet is

HERE

Available in 32oz from Amazon

HERE