|

Do you have one of the above voltage

regulators that has ceased to be a regulator? If so, and you're the curious

type, you're sure to appreciate this outstanding piece of circuitry teardown and

analysis by Baron 58 owner Derek dB.

Click

HERE to get

his PDF narrative.

Here is more voltage regulator schooling from

Derek as posted on Beech Talk

HERE:

Your vintage Baron has two regulators-- one is in use and the other is a

backup. The one regulator in use simultaneously supplies the field current to

both alternators. The field current creates a magnetic field inside the

alternator which is used to generate output current. The higher the field

current, the stronger the magnetic field and the greater the output of the

alternator. The job of the voltage regulator is to adjust the field current so

the alternator output is at a constant voltage (nominally 28.25V). If more

output current is being consumed than is being generated, the voltage drops and

the regulator increases the field voltage to keep up with the demand. The same

happens in reverse-- if the alternator output current is more than is required

by the electrical system, the bus voltage increases, which causes the regulator

to decrease the field current.

The left and right alternator outputs get joined on a common bus bar under

the nose baggage compartment and this is where the voltage regulator senses the

bus voltage. This type of setup is not a true paralleling of the alternators but

is instead two separate half systems (a left and a right) tied together. The

most efficient half system will drive the bus voltage and the other half will

"be along for the ride".

If the half systems are perfectly matched, both alternators will have

identical field vs. output curves and will be outputting exactly the same

current at exactly the same voltage with exactly the same input field current

and the alternators will share the load equally. But if there is any

difference in either half system---for example, a higher resistance on one side

in the loop from the voltage regulator field, to the alternator, to the bus bar,

back to the regulator, or if one alternator is stronger than the other---then

one alternator will supply more of the load. This is the case with almost every

Baron in existence because things are rarely perfectly matched (one can spend a

lot of time getting it close). Because the currents in these loops are large

(tens of amps for the alternators and 3 or 4 amps for the field), milli-ohm

differences can result in large voltage changes.

Sometimes, as might be your case, the half system imbalance is so large that

one alternator dominates and supplies all of the required current and

effectively keeps the other alternator off, which the system senses as a failed

alternator (the alternator out light will stay off as long as there is voltage

at the aux pin of the alternator; when the alternator output is low or zero,

that aux voltage is also low or zero). When that dominant alternator can no

longer can keep up with the current demand, its voltage will start to drop,

which will cause the regulator to output more field current, which will in turn

cause the second alternator to start to output current and take up the load (the

added field current will have little effect on the previously dominant

alternator because that alternator is at, or is reaching, its limit). This could

be what is happening when you turn on your landing lights.

Since the regulator is common to both alternators (both fields are supplied

from a single regulator pin), the problem you describe with a single alternator

is not likely due to the regulator. I would start looking at every connection in

the common bus bar-->regulator-->field-->alternator-->common bus bar loop,

(ground connections, too). If everything there is clean, then the next step is

to look at your left alternator.

Here is some Bonanza VR troubleshooting advice from Derek for a fellow Beech owner's alternator woes:

John's alternator behavior sounds a little different, and I agree

with Stuart that the root cause is probably in the field segment. I

do not think glass fuses are your problem as I believe those are only

in the 'alt out' light circuit and your voltage reading shows your alt

is indeed out.

But first, it wouldn't be Friday if I didn't include some theory---

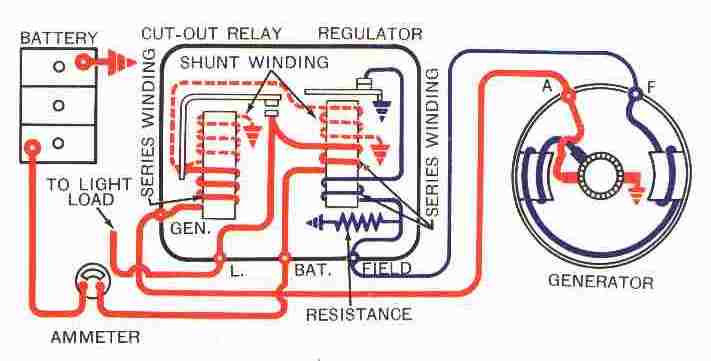

As everyone knows (or should know), electric current is produced when a

magnetic field moves past a wire and, conversely, a magnetic field is

produced when current flows through a wire. Adding more wires or

more current adds to the effect, and an efficient way of putting a bunch

of wires

in a small space is to wrap them in a coil. An alternator uses

both of these traits to produce current: first it flows a

relatively small current (the field) inside a coil to make a magnet,

then that magnet is spun inside a larger coil of wires to produce a

bigger current, which is the alternator output.

The stronger the field current in the magnetic coil, the stronger

the magnet and the higher the alternator output. The voltage

regulator is there to adjust the field current to keep a constant

voltage on the bus.

An aside-- it is sometimes said that an alternator produces AC and a

generator produces DC, but that is not exactly true as both inherently

produce AC. The generator rectifies the AC mechanically using a

commutator, whereas the alternator does so with diodes.

Oh, and another thing-- calling it a generator is technically imprecise

because an alternator is also a type of generator. What is

traditionally called a generator on vehicles is really a dynamo.

Both alternators and dynamos are generators that use a coil to create

the magnet. A third type of generator uses a permanent magnet

instead of a coil magnet; this is

called a magneto.

Something else to know is that the Beech DC generation system has a

weakness in that the voltage regulator senses the bus voltage at the end

of the very same wire that is flowing the field current. The

field current could be a couple amps, which means a very small

resistance---only a couple hundred milliohms---is all it takes to

totally screw up the voltage control loop.

So, WTF does any of this have to do with John's problem?

I think (and Stuart might be on the same page) that John has a high

resistance somewhere in the DC generation loop, quite possibly in the

field supply part of it. I further think that the intermittent

piece of it has to do with heat, i.e., at first the resistance is small

enough for the system to stay within regulation, but because that

resistance has a small voltage drop, the VR must demand more field

current to supply the load, and that higher amperage causes the resistor

to heat up, which increases the resistance, which causes more current

to be drawn, which causes more heat, which causes more resistance....

until the power loss across that resistor does not leave enough for the

field and the alternator output sags enough to turn on the 'alt out'

light. Turning off the alternator momentarily lets the resistor cool,

and the cycle restarts from the beginning.

There are lots of ways to debug the system, which include bypassing

certain circuit elements, or flat out replacing them, etc., but I think

the most quantitative way is to measure the resistance of the field loop

and eliminate the offender(s). For this you need a milliohm

meter, which is nothing more than a Kelvin bridge that anyone can cobble

together using simple components, such as this one:

http://www.aeroelectric.com/articles/LowOhmsAdapter_3.pdf

Use that to measure the resistance between the alternator output and the

field input. If it is more than, say, 300 milliohms, look for the

circuit element that has the high resistance. It could be wires,

crimps, connections, CBs, switches, etc. Check also the alt

grounds to aircraft ground (e.g., engine block) and airframe ground to

aircraft ground. Replace or fix the connections that are bad, and

don't be surprised if it is more than one (and I am not sure I agree

with Stuart that the alt switch is a breaker. If that were true,

there would be no need for a separate field breaker. And

incidentally, there *is* a way to "pull" the flush field breaker:

ground its output and turn on the master. <g>)

At least you have it easy with all the circuit elements within reach,

try measuring resistances between the left and right nacelles of a

Baron!

Good luck and try not to let the smoke out of the wires.

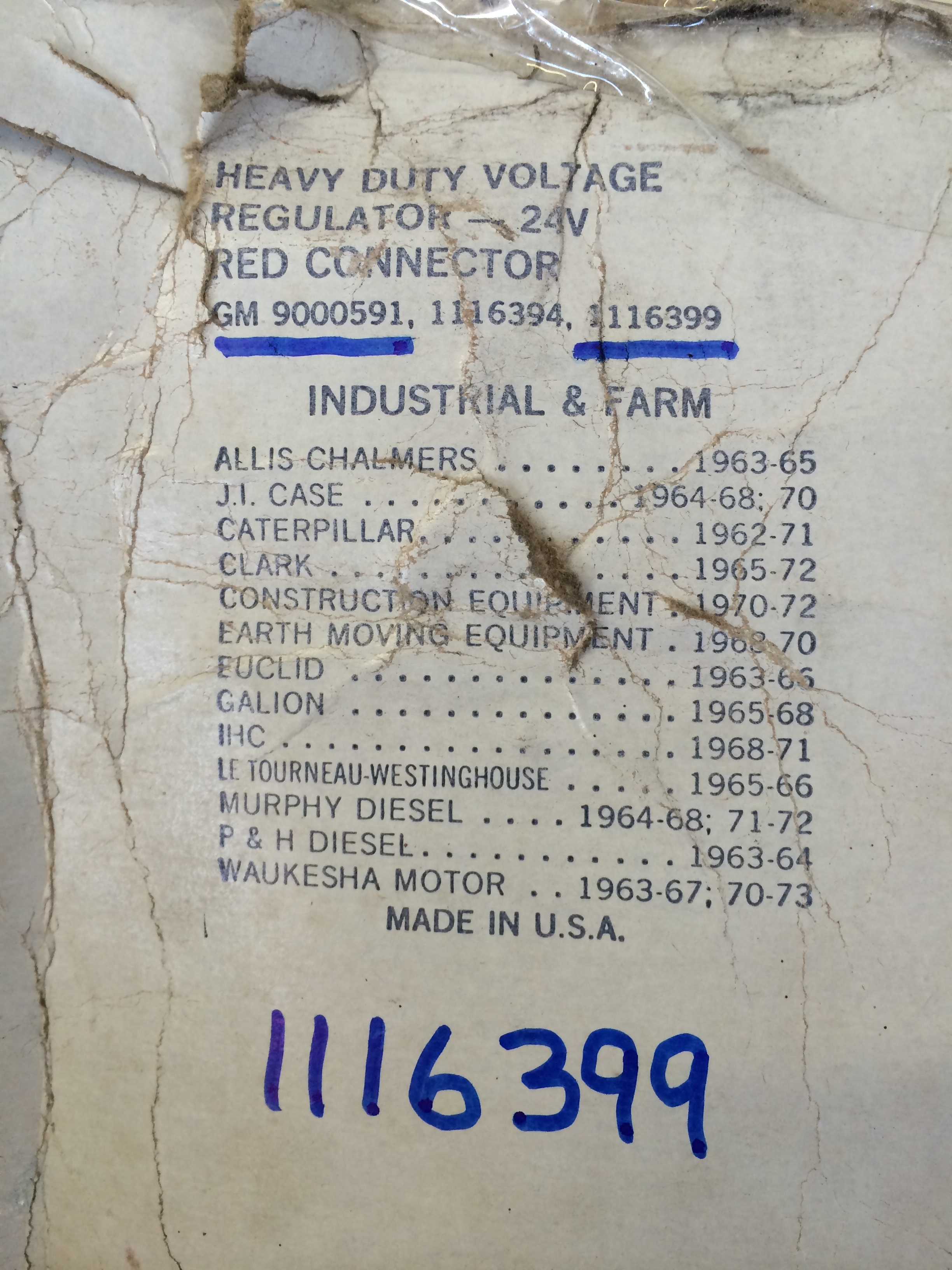

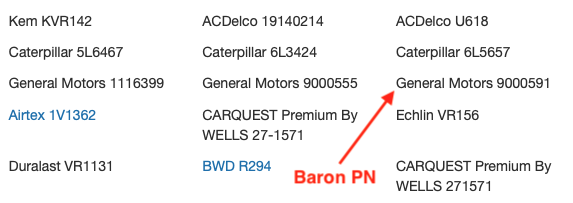

This Baron voltage regulator is typically a Delco PN: 9000591 which

consists

of very old school components that have likely not aged well. Here is a

new solid

state version that can be found, the Transpo PN: D591S and shown below.

The Transpo lists itself as a replacement for the Delco 9000591.

Amazing

that the small potted section of the Transpo is all that's required. Look for the D591S on

eBay. It holds a rock solid voltage!

Click HERE for the Transpo Catalog which shows the Delco 9000591 interchange/compatibility.

Click HERE for a $70 (1/4/2022) source for the Transpo D591S.

Be sure to consult your A&P/IA for replacement suitability.

Below is an image of the early Baron Delco

9000591 voltage regulator which is supplied in pairs for the early alternator

equipped Baron 55s. Also below you will see the Farm & Industrial applications

that this same voltage regulator used to serve back in the day. Proof once again

that Beech utilized common industrial hardware of the day in many areas of the

aircraft!

There are two power transistors within the Delco

Voltage Regulators shown above which can become tired after decades of service.

There appears to be another 24V

Regulator with a similar case and footprint in the form of Standard

Ignition's PN: VR135 which may have been supplied to agricultural

equipment. I found it available from O'Reilly Auto Parts for $58

(4/24/2024) HERE. It is pictured below.

Baron Delco

9000591 Interchange

ACDelco U618 $32 @ Amazon HERE

ACDelco U618 $32 @ Amazon HERE

Be sure to consult your A&P/IA for replacement suitability!

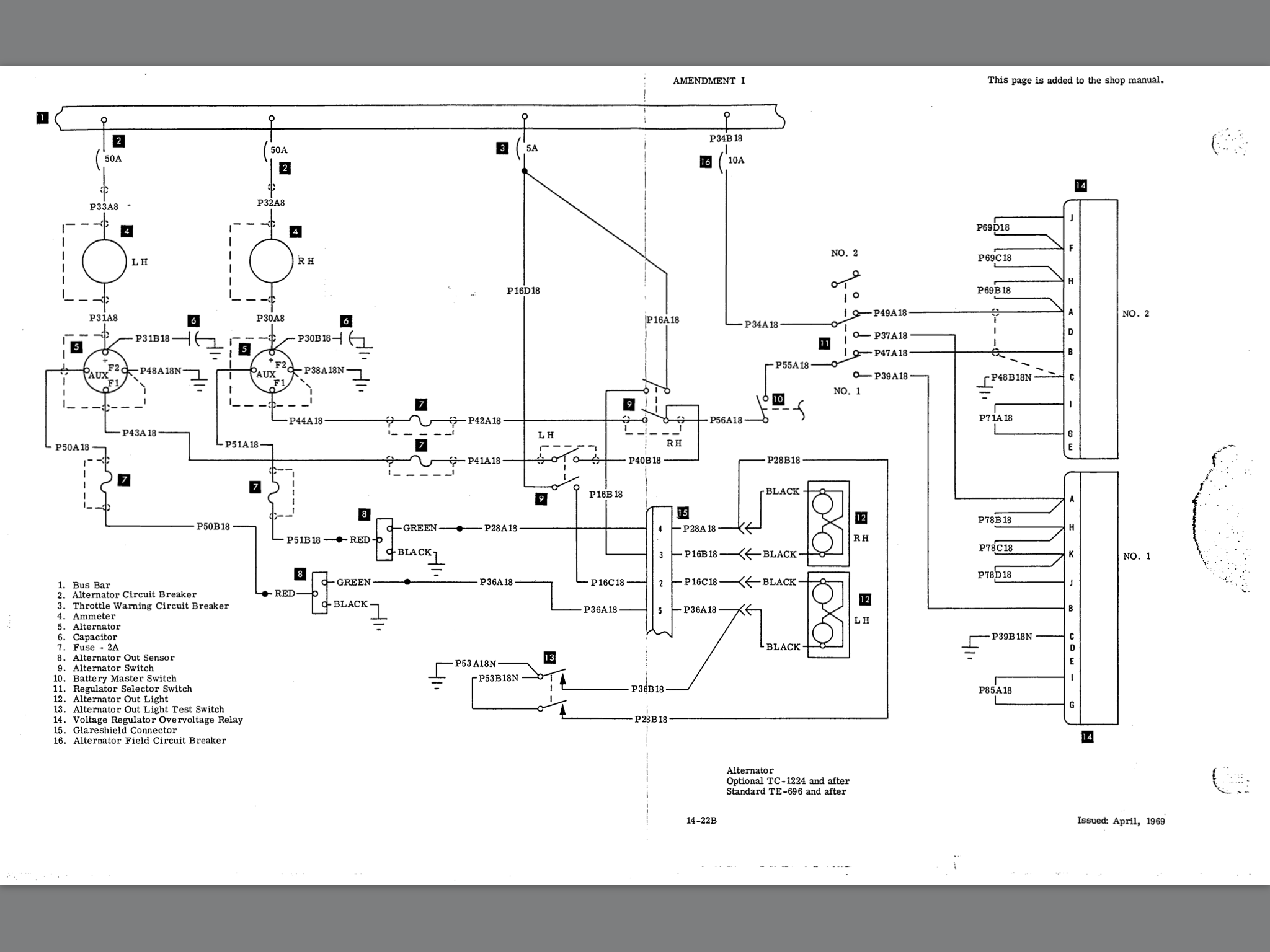

Below is an early Baron charging circuit

diagram - be sure to note the applicable SNs for it!. Check your Shop Manual for

your SN for your specific diagram:

Thanks Derek!

Early Bonanza Delco-Remy Generator Voltage Regulator

Click

HERE

for an excellent primer on the operation of the early Delco-Remy Generator

regulator.

HERE is a link to the Delco-Remy Regulator Service Bulletin from 1953.

HERE is a link to the Delco-Remy Regulator Service Bulletin from 1960.

HERE is a link to the Generator Service Bulletin from 1961

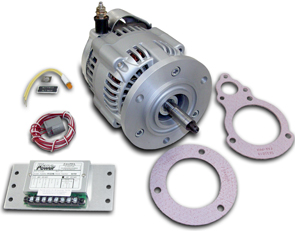

Still sick of 1950's generator and regulator technology

and brownouts in your airplane during night ops? Ready to pitch the whole

system? Consider the

Plane Power ER14-50 generator conversion kit for E-Series Bonanzas

HERE is a peek

at an older install manual for the Plane Power ER14-50 conversion kit.

|