|

I have confirmed three pireps on 1990's vintage

TCM engines with pitting lifters. My right engine is a 1999 Factory Reman and my

mechanic and I discovered several pitted lifters in the engine when we did the

top overhaul to

Superior Millennium Cylinders in 2006. My right engine had about 800 hrs on

it. I selected Superior's PMA'd lifters available through Superior

Distributors, call around and check their prices.

The recent pirep I got about

Airpower was

excellent, they priced the Superior PMA'd lifters at about half the price of

Aircraft Spruce and the PMA'd exhaust valve was half of what the cylinder shop

quoted him!

See the TCM SID 05-1B regarding lifter inspection procedures

HERE

See Superior's TCM Replacement Parts listings

HERE

PS: No, it did not NEED cylinders. When I

worked for Superior,

I was the recipient of a promotional program in 2006 to display their new Standard

Cast cylinders. By the way, after about 2000 hours the Superior Millennium

Standard Cast cylinders and my

LOP operations are going great with compressions all in the mid 70's. In all

that time only three cylinders required removal for rebuilding in 2016 and 2018!

The second lifter pirep is from an N35 owner,

Paul S.,

with an IO470N engine from a 1992 overhaul with about 1100 hours on his engine.

If you have an engine from this time span, it

might be good preventative medicine to examine your lifters for pitting. Pitted lifters

can destroy a cam and start making metal and then you know what happens? We take

your CSOB Membership Card away because you could have spent about $1,000 for the

lifters to avoid a very expensive engine overhaul.

Here is another SB for AvGas engines

assembled, overhauled or repaired with affected 657912 lifter assemblies

or 657917 lifter sockets: SB20-06

If you have a pitted lifter pirep please Email

Me

the details.

the details.

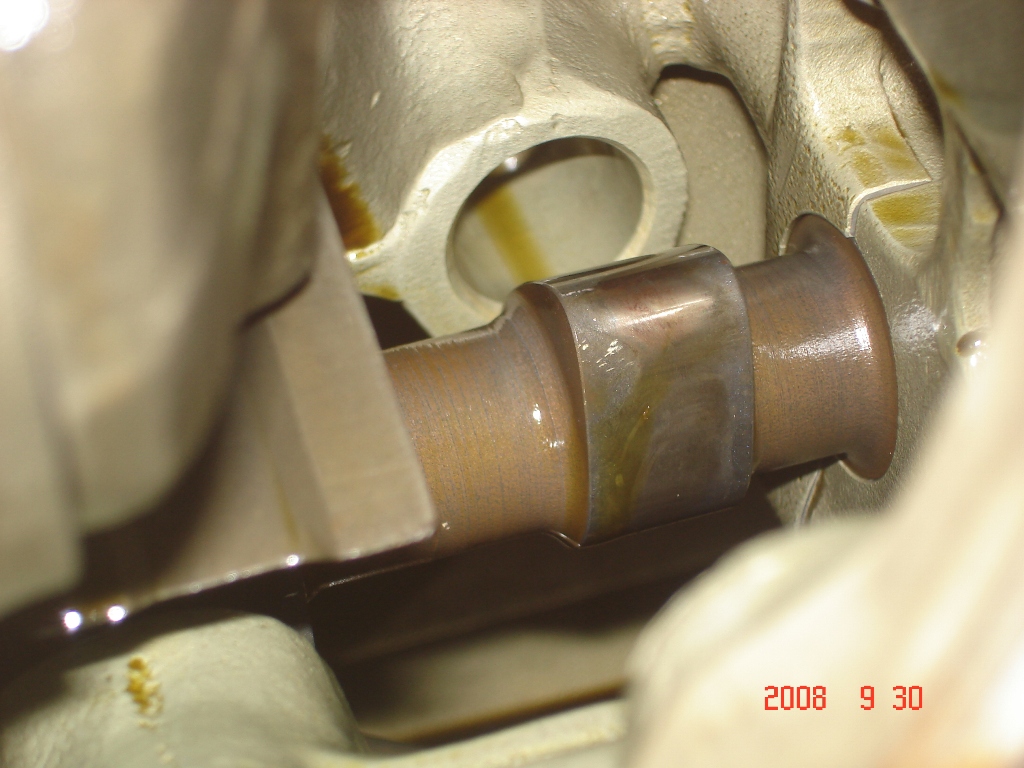

Pics of the Paul's pitted IO470N lifters circa

1992 are below.

15 October 2008 Update:

The N35 owner's TCM cylinders were all cracked at

the exhaust port. Another classic TCM failure mode for this vintage of the

1990's from what I've heard. Here is Paul's cam lobe at 900 TIS:

Tough news for Paul, he's decided on a new set of 6

new cylinders to completely freshen up his engine and get him beyond TBO.

Here is a pirep from Jim P., who reports having

pitting lifters in his 1997 vintage TCM factory reman IO470L:

We had pitted lifters and

light cam wear on a 900 SFRM IO470L installed 1997. How we found this out was we

were doing the Savannah Conversion and we were going to sell this eng to a firm

in Sweden and they are required a 10 year corrosion inspection. Fortunately we

found this before the sale and shipment, we then sold the eng as a core. Nothing

ever showed on oil samples or in the filter. The other eng had 1700 SMOH by a

local engine builder and the cam/lifters were in great condition.

Here is a pirep from a buddy of mine with a new

to him Colemill President II and this is what he finds in two of the cylinders

of his left engine:

Thankfully, he was diligent enough while his other engine

was being installed to take a look at what was going on with his left engine. He

suspects the cam is trashed and will need a costly rebuild.

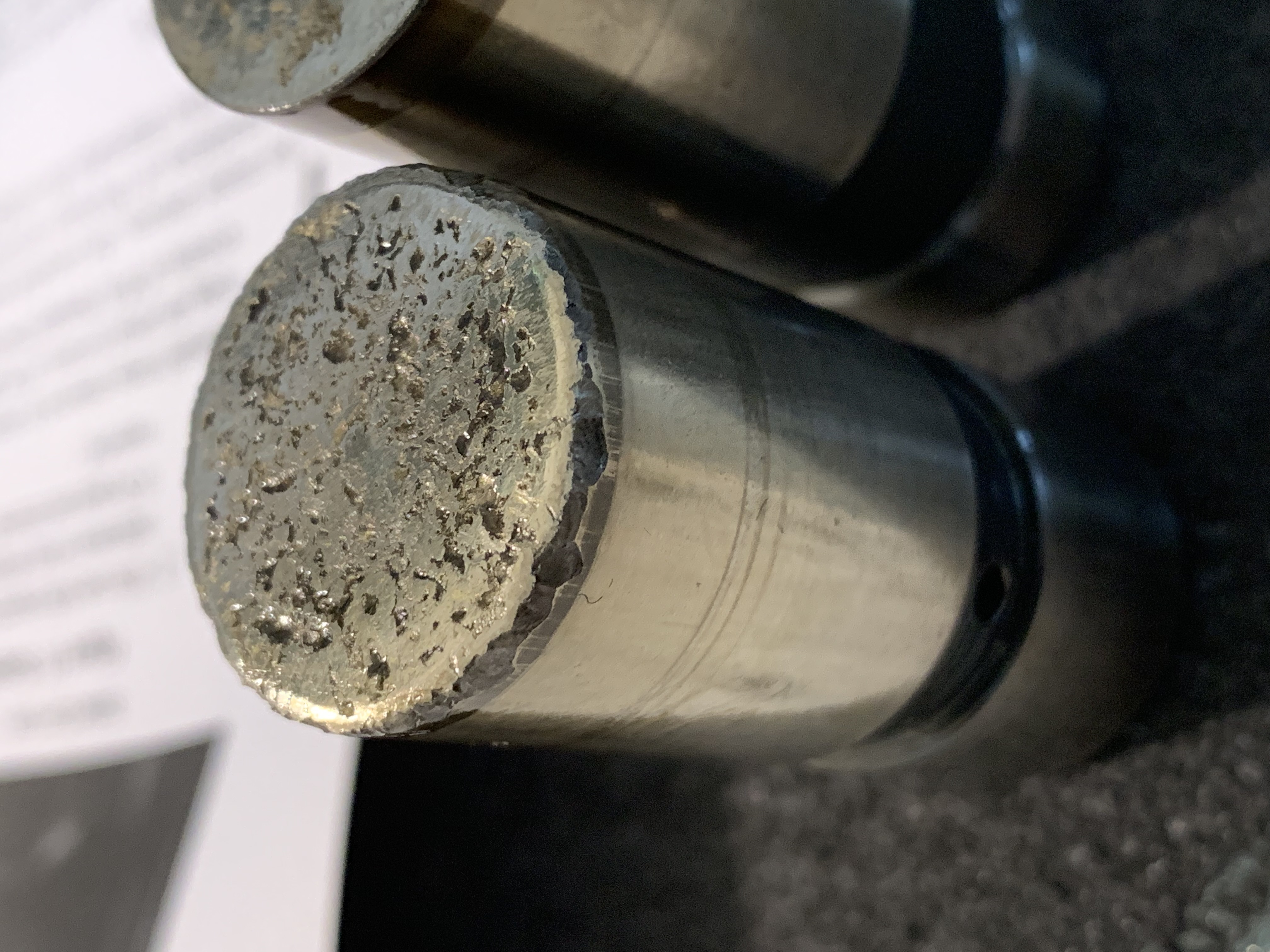

Here is another lifter spalling disaster that was

found on a 2 year old engine with 100 SMOH!

Here is another lifter spalling disaster that was

found on a 200 hour engine!

Clearly, the moral of the story is to check your

lifters at any opportunity that you can. Perhaps at a cylinder change or when a

pushrod seal is being replaced. Catch this critical component before they take

out your cam and require a case splitting financial headache! Several of the

pireps I've heard about pitting lifters, including my personal experience, were

related to engines that sat idle for a long period of time.

Below is a 600 hour SMOH lifter from a 14 year

old engine

Below are more pictures of lifter misery that has

befallen a 150SMOH Continental engine. The lifter is pitted and took out the

cam!

Below are more pictures of lifter pitting on an IO470L with <300hrs!

Click

HERE for an article by Mike Busch that discusses lifter degradation

Below is another engine that has to undergo a

teardown as a result of lifter spalling and the subsequent metal contamination

of the engine!

While you are inspecting those

lifters or changing cylinders, you may want to consider a set of these

reinforced silicone valve cover gaskets and new hardware from Guy Ginbey at Gee

Bee products

Each gasket PN: GB-534857 is $12 and

each MS16997 cap screw is $0.50

Email

or call Guy (800-556-3160) to place an order for these gaskets.

or call Guy (800-556-3160) to place an order for these gaskets.

|