|

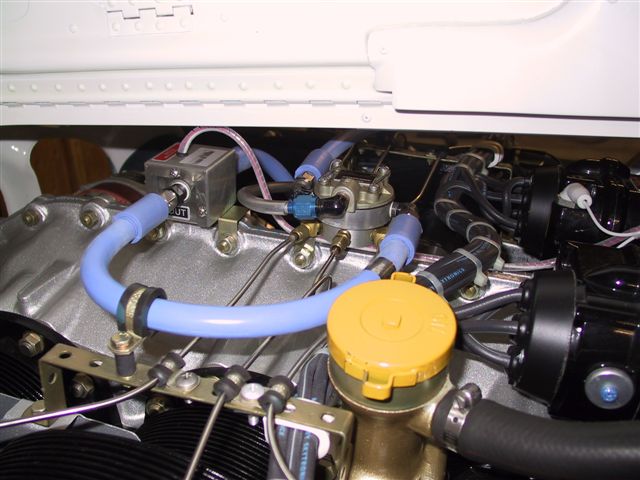

Recently a Beech Lister and

fellow Baron owner had his plane in for some starter maintenance. When the shop

began to prime the engine to test the starter, fuel began to leak all over the

engine from his fuel flow transducer mounting configuration

Here is what his

configuration looked like:

Can you see what's wrong with

this picture?

The leaks were the result of

the previous installer using hard lines for the transducer install! And aluminum

lines to BOOT!

Here is yet ANOTHER disastrous transducer

install that resulted in an Bonanza engine failure in flight, over coastal

waters of the US.

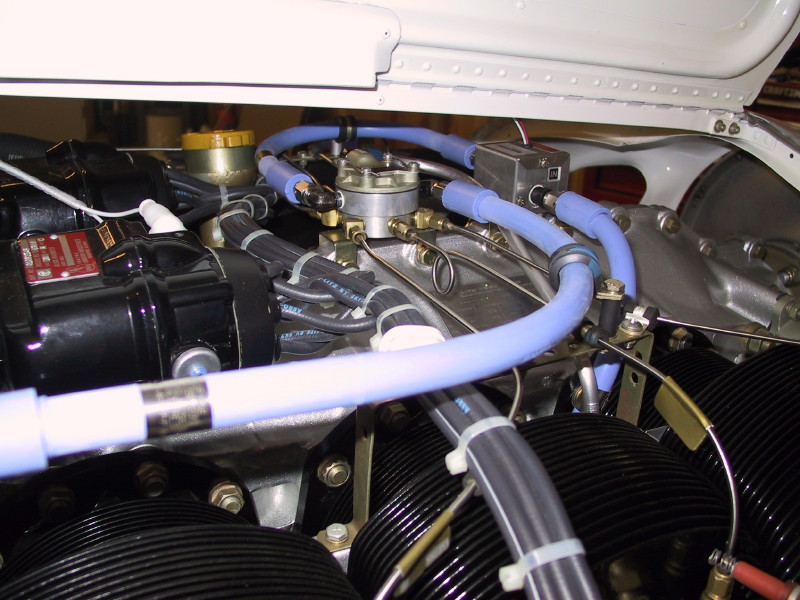

Both JPI and EI have specific install

instructions to use flexible hose for this critical connection to the fuel

spider. There is way too much vibration going on up there on top of the engine

for any hard lines to survive. This owner was extremely thankful that the leak

did not happen in flight with his family on board. Very scary!!!!!

Check your Fuel Flow install to be sure your

installer read the instructions <nbg>!

Here is his revised install, thanks to a

fortuitous find by the shop replacing his starter:

Here is another Beech Lister's transducer

install on a Bonanza:

Here is another fuel flow transducer install

on an IO-470N

So, if you have a digital aftermarket fuel

flow system installed, give your set up a look to be sure it uses flexible lines

over the engine and avoid a potentially very scary and dangerous situation.

Fuel Flow Transducer

Install WATCH OUT!

Many folks are installing digital fuel flow

instruments these days. They are awesome pieces of instrumentation and when

properly installed and calibrated can give us something on the order of 1%

accuracy of our fuel consumption and when connected to a GPS signal give us fuel

remaining at destination instantaneously!

Here is an install watch out that has been

identified by Dan M. with sleuthing help from Mike Busch. The Beech Talk thread

is

HERE and Dan's narrative follows:

|

The fittings differed

internally, and were reversed - very likely when the

Shadin was installed 12 years ago. The plane has burned

through 5 cylinders since then. Takeoff power was reduced

when at low elevation airports (not good for clearing

trees). The only reason the engine did not destroy itself

was it's low compression ratio (7:1).

Reversed the fittings, reset the metered pressure back one

turn to undo prior test, and started it up. Full power,

full rich, fuel flow went to 21.5 gph with the factory

pressure gauge right at the SL takeoff mark.

I have attached a photo of the fuel manifold. Notice the

capped restricted elbow fitting (I applied yellow torque

seal for future identification). The normal elbow fitting

is behind, pointing away, and connected to the

fire-sleeved fuel hose in the background. The brass plug

near the top with the tiny hole is the vent for the

diaphram.

|

|

|

|

So before "Joe Mechanic" starts hooking up your

transducer line to the fuel manifold, you might want to be sure you and he know what's coming out

or NOT COMING OUT of that fitting!

The fitting on the spider manifold with a

"restrictor" orifice are usually used to provide the pressure reading to the

factory fuel flow (or pressure readings converted to FF gallons/hour) gauge

inside the cabin, therefore, you do not want a full pressure spray of gas inside

the cabin if the hose cracks. Others have commented these fittings SOMETIMES can

be found painted red.

The problems seem to arise when the restrictor

fitting is inadvertently or mistakenly placed on the supply side!

Here is a bulletin on it:

Continental: IO470K; Improper fuel fittings; ATA 7324 A technician states, "(We

performed...) the fuel injection setup per TCM SID 97-3E, but the electronic

fuel flow computer showed flow below specifications. We were unable to increase

flow sufficiently by increasing pressure. (Subsequent inspection revealed

the...) inlet elbow fittings (P/N's 631658 and 628437) had been previously

reversed, probably twelve years prior during installation of an electronic fuel

flow transducer. Part

631658 has a restrictor orifice, while 628437 does not. The parts look

identical externally. It takes a very careful (observation) to see the internal

difference. The TCM engine overhaul manual does not mention this.

The TCM parts manual shows the different part numbers, but does not describe

the differences. This would be a very easy mistake to make, and very difficult

to diagnose later. (Again), this problem probably started twelve years ago, and

was not detected or corrected until now. This airplane had five cylinders

changes during this time - (most likely) caused by lean operation at full power.

The aircraft (may not have...) generated full power on takeoff due to a very

lean, full rich mixture. It is critical to communicate this to mechanics and

owners to prevent a dangerous condition."

PS: Good Call on installing a FF

instrument and hooking it to your GPS! Takes a lot of the old school estimation

out of "Wonder if I have enough fuel to make it?"

Here is a narrative by Beech owner

Mike T. regarding his search for fittings for his fuel flow transducer install:

I finally found a source of the steel fittings I need to install FloScan

transducers on a pair of TCM engines.

I wasn't having success with suppliers of aviation-type hardware but checking

with suppliers of hydraulic fittings got quick results.

What I need are 1/8 - 1/4 male-male NPT FF pipe nipples, SAE 104137. They

cost less than $2 each. Parker is one mfg.

These particular fittings might not be appropriate for any individual engine.

It depends what fitting is on the flow divider, which may or may not conform to

the TCM parts catalog. (Going down the aviation road got scary as one potential

vendor got an "expert" involved who mentioned the necessity of meeting

"aerospace standards" and such.)

Hydraulic supply houses might be a good source for other types of fittings we

use. Some sell a big variety of AN fittings, for instance, dwarfing the

selection offered by popular aviation vendors. (A couple of years ago I paid an

aviation house almost $30 for a brass elbow fitting that's readily available in

the real world for $2.05.)

Certainly, it's up to the installing mechanic to determine suitability.

|